ARK Stainless Inc. is a leading manufacturer and supplier of high-quality Titanium Bars, available in a range of grades including Gr 1, Gr 2, Gr 5, and Gr 9. Renowned for their outstanding corrosion resistance, superior strength-to-weight ratio, and excellent durability, these titanium bars are ideal for use in aerospace, marine, chemical processing, medical, and industrial applications. Their resistance to harsh environments, including saltwater, acids, and oxidizing chemicals, makes them a reliable choice for critical and high-performance uses.

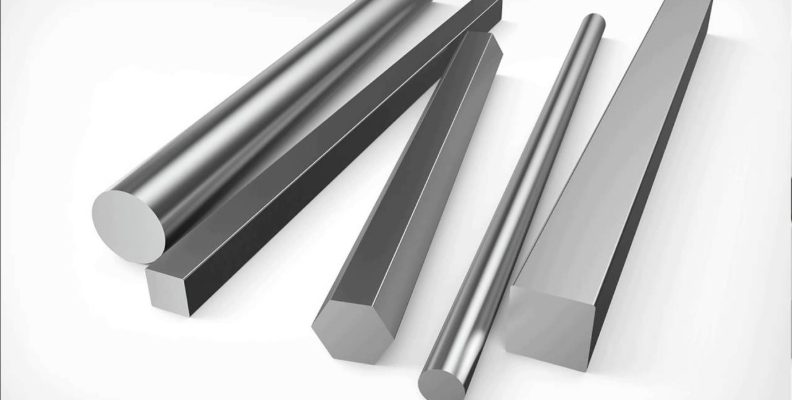

Our Titanium Bars are crafted from premium titanium alloys, offering excellent machinability, weldability, and long-term performance. Titanium Gr 1 and Gr 2 Bars provide outstanding corrosion resistance and are preferred for applications requiring high ductility and formability. Gr 5 and Gr 9 Bars, known for their superior strength and thermal stability, are well-suited for structural components subjected to extreme conditions. These bars are available in a variety of diameters, lengths, and surface finishes to meet specific project requirements.

Produced in adherence to international quality standards such as ASTM B348 and ASME SB348, our titanium bars undergo stringent quality control processes including ultrasonic testing, mechanical property evaluation, and dimensional inspection. At ARK Stainless Inc., we are committed to delivering precision-engineered titanium bars that ensure performance, safety, and reliability across diverse industrial sectors.

| Grade | C | Fe | H | N | O | Al | V | Ti |

|---|---|---|---|---|---|---|---|---|

| Titanium Gr 1 Round Bars | 0.08 max | 0.20 max | 0.015 max | 0.03 max | 0.18 max | — | — | Balance |

| Titanium Gr 2 Round Bars | 0.08 max | 0.30 max | 0.015 max | 0.03 max | 0.25 max | — | — | Balance |

| Titanium Gr 5 Round Bars | 0.08 max | 0.40 max | 0.015 max | 0.05 max | 0.20 max | 5.5–6.75 | 3.5–4.5 | Balance |

| Titanium Gr 9 Round Bars | 0.08 max | 0.25 max | 0.015 max | 0.03 max | 0.15 max | 2.5–3.5 | — | Balance |

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Hardness (Rockwell) | Density (g/cm³) | Melting Point (°C) |

|---|---|---|---|---|---|---|---|

| Titanium Gr 1 Round Bars | 240 min | 170 min | 24 min | 70–90 | Rc 60–70 | 4.51 | 1665 |

| Titanium Gr 2 Round Bars | 345 min | 275 min | 20 min | 70–90 | Rc 65–74 | 4.51 | 1665 |

| Titanium Gr 5 Round Bars | 895 min | 828 min | 10 min | 334 | Rc 36 | 4.43 | 1604 |

| Titanium Gr 9 Round Bars | 620 min | 483 min | 15 min | 200–250 | Rc 20–25 | 4.48 | 1620 |

Titanium Gr 1 Bars are known for their excellent corrosion resistance, superior weldability, and outstanding formability. These bars are commonly used in applications that demand high ductility and resistance to aggressive environments, including aerospace structures, marine hardware, chemical processing equipment, medical implants, and heat exchangers.

Available in a variety of diameters, lengths, and finishes, our Titanium Gr 1 Bars are manufactured to exact tolerances and are offered in hot-rolled, cold-drawn, or centerless ground finishes to meet your specific needs. Their high strength-to-weight ratio and non-magnetic nature make them a preferred material for sensitive and high-performance applications.

Our Titanium Gr 1 Bars undergo comprehensive quality control procedures including chemical analysis, mechanical testing, ultrasonic testing, and dimensional inspections. Compliant with international standards such as ASTM B348 and ASME SB348, these bars are supplied with complete traceability and mill test certificates. Packaging is done with utmost care using wooden boxes, plastic wrapping, or steel bundling to ensure safe delivery to your destination.

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Titanium Gr 1 | 3.7025 | R50250 |

Titanium Gr 2 Bars are commercially pure titanium products widely known for their excellent corrosion resistance, good strength, and superior weldability. These bars are highly versatile and are used across a broad range of industries including marine, chemical processing, desalination, power generation, and medical technology due to their excellent performance in both oxidizing and reducing environments.

ARK Stainless Inc. supplies Titanium Gr 2 Bars in various shapes and finishes including round, square, hex, and flat bars. These bars are available in hot-rolled, cold-drawn, or precision-ground finishes, offering outstanding workability and structural stability even under high-stress conditions. Their high resistance to corrosion, especially in chloride and seawater environments, makes them ideal for offshore and industrial applications.

Each bar undergoes strict testing protocols, including mechanical strength testing, chemical composition analysis, ultrasonic inspection, and surface quality checks. Our Titanium Gr 2 Bars conform to global standards like ASTM B348 and ASME SB348 and are delivered with full traceability and comprehensive mill test certificates. Packaging is tailored to ensure product protection and safe delivery, using methods like wooden crates, plastic wrapping, and steel banding.

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Titanium Gr 2 | 3.7035 | R50400 |

Titanium Gr 5 Bars (also known as Ti-6Al-4V) are a high-performance titanium alloy composed of 6% Aluminum and 4% Vanadium. These bars are known for their superior strength-to-weight ratio, excellent corrosion resistance, and outstanding mechanical properties at elevated temperatures. They are widely used in aerospace, defense, medical, marine, and high-performance engineering industries where high strength and lightweight are crucial.

ARK Stainless Inc. offers Titanium Gr 5 Bars in various shapes including round, hex, square, and flat bars. These bars are available in hot-rolled, cold-drawn, and precision-ground finishes with tight dimensional tolerances. Titanium Grade 5 offers nearly twice the strength of commercially pure grades while retaining good ductility and fatigue resistance, making it ideal for structural components, engine parts, surgical implants, and offshore equipment.

Our Titanium Gr 5 Bars are manufactured to meet rigorous industry standards such as ASTM B348 and ASME SB348. Each batch undergoes extensive testing including ultrasonic inspection, mechanical and chemical analysis, and surface integrity checks. Fully traceable with mill test certificates, these bars are packaged using wooden crates, plastic wrapping, or steel bundling as per customer requirements to ensure safe and damage-free delivery.

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Titanium Gr 5 | 3.7165 | R56400 |

Titanium Gr 9 Bars, also known as Ti-3Al-2.5V, are lightweight, corrosion-resistant bars with enhanced strength and superior formability compared to commercially pure titanium grades. These bars strike a perfect balance between the weldability of Gr 2 and the strength of Gr 5, making them ideal for high-performance applications where moderate strength and excellent corrosion resistance are required.

Commonly used in aerospace structures, sporting goods, marine components, hydraulic systems, and high-performance bicycle frames, Titanium Gr 9 Bars are supplied by ARK Stainless Inc. in various shapes and surface finishes including round, square, hex, and flat bars. These bars maintain mechanical stability even under high pressure and temperature, while offering exceptional fatigue resistance and longevity.

Manufactured in compliance with international standards such as ASTM B348 and ASME SB348, our Titanium Gr 9 Bars undergo stringent testing protocols including mechanical strength evaluation, ultrasonic inspection, chemical composition analysis, and visual and dimensional checks. Every bar is supplied with complete traceability and mill test certificates, and packaged securely using wooden crates, steel banding, or customized solutions to ensure product safety during transit.

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Titanium Gr 9 | 3.7195 | R56320 |