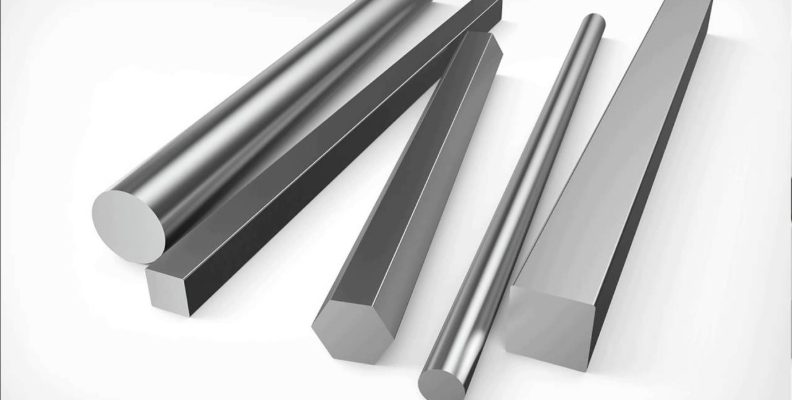

Our extensive inventory includes Bright Bars, Forged Bars, and Rectangular Bars, available in various grades, sizes, and specifications to suit diverse industrial needs. Whether you require Stainless Steel, Duplex & Super Duplex, Inconel, Monel, Nickel, Hastelloy, Alloy Steel, Alloy 20, Brass, Tantalum, Copper Nickel, Carbon Steel, or Titanium, we offer solutions that meet international quality standards, ensuring high performance in demanding environments.

Manufactured using premium-quality materials, our bars are designed for superior corrosion resistance, high tensile strength, and excellent mechanical properties. We offer customization options, allowing customers to choose between matte, mirror, or silver finishes based on their specific project requirements. Each product undergoes strict quality control and precision engineering to ensure durability, reliability, and long-term performance.

Designed for critical industrial applications, our bars support industries such as Oil & Gas, Construction, Chemical Processing, Power Generation, Aerospace, Automotive, Pharmaceuticals, and Heavy-Duty Engineering. Whether used for structural frameworks, machining components, industrial fittings, or manufacturing equipment, our products offer high-strength, wear-resistant, and corrosion-proof solutions.

At ARK Stainless Inc., we are committed to delivering top-tier bar solutions with customization options in terms of dimensions, finishes, and material grades. Our dedication to innovation, quality, and excellence ensures that our bars contribute to enhanced efficiency, reduced maintenance costs, and long-term reliability in industrial applications worldwide.

| Material | Standard | Available Grades | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| Stainless Steel | ASTM A276 / A479 | 304 | 304L | 304H | 309 | 310 | 310S | 316 | 316L | 316Ti | 317L |

| 321 | 321H | 347 | 347H | 410 | 420 | 430 | 446 | 904L | |||

| Duplex / Super Duplex | ASTM A276 / A479 | Duplex S31803 / S32205 | Super Duplex S32750 / S32760 | ||||||||

| Nickel Alloys | ASTM B160 / B164 | Nickel 200 | Nickel 201 | Inconel 600 | Inconel 625 | Inconel 718 | Incoloy 800 | Incoloy 825 | Monel 400 | Monel K500 | |

| Alloy Steel | ASTM A182 / A336 | F1 | F5 | F9 | F11 | F12 | F22 | F91 | F92 | ||

| Titanium | ASTM B348 | Gr 1 | Gr 2 | Gr 5 | Gr 9 | ||||||

| Carbon Steel | ASTM A36 / A105 | Mild Steel | High Tensile | S355J2+N | ST 52 | EN 353 | |||||

| Copper Nickel | ASTM B151 | CuNi 70/30 | CuNi 90/10 | ||||||||

| Other Alloys | - | Alloy 20 | Hastelloy | Brass | Beryllium Copper | Tantalum | SMO 254 | Aluminium | |||

| Type | Material | Grades | Size Range | Standards |

|---|---|---|---|---|

| Round, Square, Hex, Flat, Bright, Forged | Stainless Steel | SS 304/304L/304H | 3mm - 350mm | ASTM A276, A479 |

| SS 309/310/310S | ||||

| SS 316/316L/316Ti | ||||

| SS 317/317L | ||||

| SS 321/321H | ||||

| SS 347/347H | ||||

| SS 410/420 | ||||

| SS 431/430/446 | ||||

| SS 904L/15-5PH/17-4PH | ||||

| Round, Square, Hex, Flat | Duplex / Super Duplex | Duplex S31803 / S32205, Super Duplex S32750 / S32760 | 3mm - 350mm | ASTM A276, A479 |

| Round, Hex | Nickel Alloys | Nickel 200/201, Inconel 600/625/718, Incoloy 800/825 | 6mm - 200mm | ASTM B160, B164 |

| Round, Hex | Monel | Monel 400/K500 | 6mm - 200mm | ASTM B164 |

| Round, Hex | Hastelloy | Hastelloy C22, C276 | 6mm - 150mm | ASTM B574 |

| Round, Square, Hex | Alloy Steel | F1, F5, F9, F11, F12, F22, F91, F92 | 10mm - 300mm | ASTM A182 |

| Round, Square | Carbon Steel | A36, S355J2+N, ST 52, EN 353 | 10mm - 300mm | ASTM A105, A350 |

| Round, Hex | Titanium | Gr 1, Gr 2, Gr 5, Gr 9 | 6mm - 150mm | ASTM B348 |

| Bar Type | Shape | Size Range (mm) | Length (mm) | Standard |

|---|---|---|---|---|

| Round Bar | Bright Bar | 3mm - 100mm | 3000 - 6000 | ASTM A276 / A479 |

| Forged Bar | 100mm - 600mm | Up to 9000 | ||

| Hex Bar | Hexagonal | 8mm - 60mm | 3000 - 6000 | ASTM A276 |

| Flat Bar | Rectangular | 20mm - 200mm Width | 3000 - 6000 | ASTM A276 |

| Square Bar | Square | 10mm - 150mm | 3000 - 6000 | ASTM A276 |

| Rectangular Bar | Rectangular | 10mm - 100mm Width | 3000 - 6000 | ASTM A276 |

| Bar Type | Material | Pressure-Temperature Ratings (PSI) | Standard | ||||

|---|---|---|---|---|---|---|---|

| -20°F to 100°F | 200°F | 400°F | 600°F | 800°F | |||

| Round Bar | SS 304/304L/304H | 150 | 130 | 115 | 95 | 80 | ASTM A276 / A479 |

| SS 316/316L/316Ti | 160 | 135 | 120 | 100 | 85 | ||

| SS 321/321H | 155 | 133 | 118 | 98 | 83 | ||

| Hex Bar | Duplex Steel S31803/S32205 | 175 | 150 | 130 | 110 | 95 | ASTM A276 |

| Flat Bar | Inconel 600/625 | 190 | 165 | 145 | 125 | 110 | ASTM B166 |

| Square Bar | Mild Steel A36 | 140 | 120 | 100 | 85 | 70 | ASTM A36 |

| Bright Bar | Alloy Steel F22 | 170 | 145 | 125 | 105 | 90 | ASTM A182 |

| Forged Bar | Titanium Gr 5 | 200 | 175 | 150 | 130 | 110 | ASTM B348 |

| Material | Grade | Dimensional Tolerances (mm) | Straightness & Ovality Tolerances | Standard | ||||

|---|---|---|---|---|---|---|---|---|

| Diameter | Width | Length | Straightness (mm/m) | Max Ovality (%) | Flatness (%) | |||

| Stainless Steel | SS 304/304L/304H | ±0.5 | ±0.4 | ±1.0 | 0.5 | 1.5% | 2.0% | ASTM A276 / A479 |

| SS 316/316L/316Ti | ±0.6 | ±0.5 | ±1.2 | 0.6 | 1.8% | 2.2% | ||

| SS 321/321H | ±0.7 | ±0.6 | ±1.5 | 0.7 | 2.0% | 2.5% | ||

| Duplex Steel | S31803 / S32205 | ±0.6 | ±0.4 | ±1.2 | 0.5 | 1.5% | 2.0% | ASTM A276 |

| Nickel Alloy | Nickel 200/201 | ±0.5 | ±0.3 | ±1.0 | 0.4 | 1.2% | 1.8% | ASTM B160 |

| Alloy Steel | Alloy Steel F22 | ±0.6 | ±0.5 | ±1.2 | 0.6 | 1.8% | 2.2% | ASTM A182 |

| Brass | Brass Round Bar | ±0.6 | ±0.4 | ±1.2 | 0.5 | 1.6% | 2.0% | ASTM B16 |

| Carbon Steel | Mild Steel A36 | ±0.5 | ±0.3 | ±1.0 | 0.4 | 1.2% | 1.8% | ASTM A36 |

| Titanium | Titanium Gr 5 | ±0.5 | ±0.3 | ±1.0 | 0.5 | 1.5% | 2.0% | ASTM B348 |

Bars are widely used across various industries due to their strength, durability, and versatility. Some of the key applications include:

Used in aircraft components, landing gear, and structural reinforcements due to their high strength and corrosion resistance.

Essential for manufacturing drive shafts, engine components, and suspension parts in vehicles.

Used in drilling equipment, pipeline supports, and offshore platform structures.

Integral for reinforcing structures, bridges, and industrial frameworks.

Applied in ship structures, propeller shafts, and corrosion-resistant marine fittings.

Used in turbines, power transmission components, and generator shafts.

Stainless steel and titanium bars are widely used in surgical instruments, implants, and medical devices.

Used in food processing machinery, conveyor systems, and sanitary equipment.

The manufacturing of bars involves several precise steps to ensure high strength, durability, and compliance with industry standards. This includes raw material selection, melting, casting, hot rolling, heat treatment, machining, finishing, and quality inspection.

High-quality raw materials such as stainless steel, alloy steel, nickel alloys, and titanium are chosen based on application requirements.

The selected raw materials are melted in electric arc or induction furnaces and then cast into billets or blooms.

The cast billets are heated and passed through rolling mills to achieve the desired shape – round, flat, or hexagonal bars.

Bars undergo processes like annealing, normalizing, quenching, and tempering to enhance mechanical properties and relieve stresses.

Bars may undergo cold drawing for precise dimensions and machining for further shaping and smooth surface finishing.

Bars are treated with polishing, grinding, pickling, or coating to enhance corrosion resistance and surface quality.

Bars undergo dimensional checks, ultrasonic testing, hardness testing, and other quality assurance processes to meet industry standards.

The finished bars are securely packed, labeled with specifications, and dispatched for safe transportation.

Square bars are solid metal bars with a square cross-section, widely used in construction, manufacturing, and engineering applications. These bars are available in various materials such as stainless steel, carbon steel, alloy steel, and more, ensuring high strength, durability, and corrosion resistance.

| Size (mm) | Length (Standard) | Material Options |

|---|---|---|

| 10 x 10 | 3m / 6m | SS, CS, Alloy Steel |

| 20 x 20 | 3m / 6m | SS, CS, Alloy Steel |

| 30 x 30 | 3m / 6m | SS, CS, Alloy Steel |

| 50 x 50 | 3m / 6m | SS, CS, Alloy Steel |

Hex bars are precision-engineered metal bars with a hexagonal cross-section, widely used in industrial, engineering, and construction applications. Their unique shape provides increased strength and grip for various machining and fastening applications. Available in a variety of materials, including stainless steel, carbon steel, alloy steel, and non-ferrous metals, hex bars offer excellent durability and corrosion resistance.

| Hex Bar Size (mm) | Across Flats (mm) | Weight (kg/m) | Available Lengths |

|---|---|---|---|

| 10 | 8.66 | 0.59 | 3m / 6m |

| 20 | 17.32 | 2.35 | 3m / 6m |

| 30 | 25.98 | 5.3 | 3m / 6m |

| 40 | 34.64 | 9.4 | 3m / 6m |

| 50 | 43.30 | 14.7 | 3m / 6m |

Rectangular bars, also known as flat bars with a rectangular cross-section, are widely used in structural, industrial, and machining applications. Their uniform shape and precise dimensions make them ideal for frameworks, brackets, supports, and general fabrication. Rectangular bars are available in a variety of materials, including stainless steel, carbon steel, alloy steel, and non-ferrous metals, ensuring durability and corrosion resistance.

| Width (mm) | Thickness (mm) | Weight (kg/m) | Available Lengths |

|---|---|---|---|

| 20 | 5 | 0.78 | 3m / 6m |

| 40 | 6 | 1.88 | 3m / 6m |

| 50 | 8 | 3.14 | 3m / 6m |

| 75 | 10 | 5.9 | 3m / 6m |

| 100 | 12 | 9.42 | 3m / 6m |

Flat bars are versatile metal bars with a rectangular cross-section, commonly used in structural, industrial, and fabrication applications. They provide excellent strength, machinability, and corrosion resistance, making them suitable for construction, automotive, and engineering industries. Available in various materials, including stainless steel, carbon steel, alloy steel, and other specialty grades, flat bars offer durability and precision for various applications.

| Width (mm) | Thickness (mm) | Weight (kg/m) | Available Lengths |

|---|---|---|---|

| 25 | 5 | 0.98 | 3m / 6m |

| 50 | 6 | 2.35 | 3m / 6m |

| 75 | 8 | 4.71 | 3m / 6m |

| 100 | 10 | 7.85 | 3m / 6m |

| 150 | 12 | 14.14 | 3m / 6m |

Bright bars are precision-engineered metal bars with a smooth, bright surface finish achieved through cold drawing, peeling, and grinding processes. These bars are widely used in applications requiring high dimensional accuracy, superior surface quality, and enhanced mechanical properties. Available in round, square, and hexagonal shapes, bright bars are used in industries like automotive, construction, and manufacturing.

| Shape | Size Range (mm) | Tolerance | Surface Finish |

|---|---|---|---|

| Round | 3 - 100 | ±0.05 mm | Bright / Polished |

| Square | 6 - 80 | ±0.10 mm | Bright / Smooth |

| Hexagonal | 6 - 75 | ±0.08 mm | Bright / Machined |

Forged bars are produced through hot forging processes, ensuring superior strength, durability, and resistance to extreme conditions. These bars are commonly used in high-stress applications like aerospace, defense, heavy machinery, and power generation. Available in round, square, and rectangular shapes, forged bars offer enhanced mechanical properties and excellent grain structure.

| Shape | Size Range (mm) | Forging Process | Heat Treatment |

|---|---|---|---|

| Round | 20 - 600 | Open Die / Closed Die | Annealed / Normalized |

| Square | 25 - 500 | Open Die | Quenched & Tempered |

| Rectangular | 30 - 400 | Open Die | Stress Relieved |