ARK Stainless Inc. is a leading Manufacturer and Exporter of premium-quality Forged Fittings based in Mumbai, India. We are dedicated to producing high-performance Forged Fittings crafted from superior-grade raw materials, carefully inspected and processed by skilled professionals to ensure strength, precision, and reliability.

Our Forged Fittings are manufactured in full compliance with National and International Standards, offering excellent durability and performance under high-pressure and high-temperature conditions. With a focus on innovation and quality, ARK Stainless Inc. has earned the trust of customers across diverse industries worldwide.

| Material | Standard | Available Grades | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| Stainless Steel | ASTM A182 F | 304 | 304H | 309 | 310 | 316 | 316L | 317L | 321 | 347 | 904L |

| Alloy Steel | ASTM A182 F | F1 | F11 | F12 | F22 | F91 | F5 | F9 | |||

| Aluminum | ASTM B209 / B221 / B247 | 1100 | 2011 | 2014 | 2024 | 3003 | 5052 | 6061 | 6063 | 7075 | |

| Carbon Steel | ASTM A105 / A350 LF2 | WPB | WPBW | WPHY 42 | WPHY 46 | WPHY 52 | WPHY 60 | WPHY 65 | WPHY 70 | ||

| Nickel Alloy | ASTM B564 | Inconel 600 | Monel 400 | Alloy 20 | Inconel 825 | Inconel 601 | Inconel 625 | Nickel 200 | Hastelloy C276 | Nickel 201 | |

| Titanium | ASTM B348 / B381 / B367 | Grade 1 | Grade 2 | Grade 5 | Grade 7 | ||||||

| Monel | ASTM B564 / B865 | Monel 400 | Monel K500 | ||||||||

| Hastelloy | ASTM B619 / B622 | C-22 | C-276 | B-2 | Hastelloy X | ||||||

| Duplex & Super Duplex Stainless Steel | ASTM A182 / A351 | Duplex 2205 | Duplex 2304 | Super Duplex 2507 | |||||||

| Type | Connection | Size Range (NPS) | Pressure Rating (Class) | Standard | Application |

|---|---|---|---|---|---|

| Elbow (90°/45°) | Socket Weld | 1/8” - 4” | 2000 / 3000 / 6000 | ASME B16.11 | Direction change in pipe systems |

| Forged Tee | Socket Weld / Threaded | 1/8” - 4” | 2000 / 3000 / 6000 | ASME B16.11 | 3-way fluid distribution |

| Forged Cross | Socket Weld / Threaded | 1/8” - 4” | 2000 / 3000 / 6000 | ASME B16.11 | 4-way flow intersection |

| Coupling (Full/Half/Reducing) | Socket Weld / Threaded | 1/8” - 4” | 2000 / 3000 / 6000 | ASME B16.11 | Pipe joining or reduction |

| Forged Pipe Cap | Socket Weld / Threaded | 1/8” - 4” | 2000 / 3000 / 6000 | ASME B16.11 | End closure for pipe run |

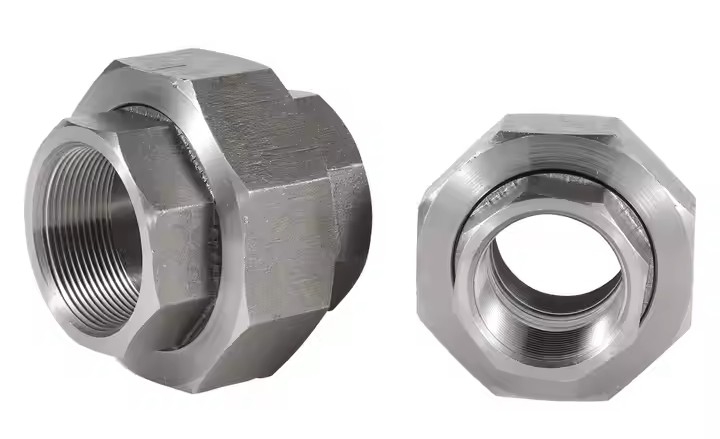

| Forged Union | Threaded | 1/8” - 4” | 2000 / 3000 | ASME B16.11 / MSS-SP-83 | Easy disassembly and reconnection |

| Forged Bushing | Threaded | 1/8” - 4” | 2000 / 3000 | ASME B16.11 | Reducing pipe size |

| Forged Nipple | Threaded | 1/8” - 4” | 2000 / 3000 | ASME B16.11 / MSS-SP-95 | Pipe extensions and connections |

| Fitting Type | Size (Inch) | Dimensions (mm) | Wall Thickness | Standard | |

|---|---|---|---|---|---|

| Outer Diameter (OD) | Center-to-End / Length | ||||

| Elbow 90° | 1/2" | 21.3 | 33 | 3.75 | ASME B16.11 |

| 3/4" | 26.7 | 38 | 3.90 | ||

| 1" | 33.4 | 44 | 4.55 | ||

| Forged Tee | 1/2" | 21.3 | 33 | 3.75 | ASME B16.11 |

| 3/4" | 26.7 | 38 | 3.90 | ||

| 1" | 33.4 | 44 | 4.55 | ||

| Forged Cross | 1/2" | 21.3 | 33 | 3.75 | ASME B16.11 |

| 3/4" | 26.7 | 38 | 3.90 | ||

| 1" | 33.4 | 44 | 4.55 | ||

| Coupling | 1/2" | 21.3 | 32 | 3.75 | ASME B16.11 |

| 3/4" | 26.7 | 35 | 3.90 | ||

| 1" | 33.4 | 41 | 4.55 | ||

| Forged Pipe Cap | 1/2" | 21.3 | 25 | 3.75 | ASME B16.11 |

| 3/4" | 26.7 | 28 | 3.90 | ||

| 1" | 33.4 | 32 | 4.55 | ||

| Forged Union | 1/2" | 21.3 | 48 | 3.75 | MSS SP-83 |

| 3/4" | 26.7 | 53 | 3.90 | ||

| 1" | 33.4 | 60 | 4.55 | ||

| Forged Bushing | 1/2" x 1/4" | 21.3 x 13.7 | 22 | 3.75 | ASME B16.11 |

| 3/4" x 1/2" | 26.7 x 21.3 | 25 | 3.90 | ||

| 1" x 3/4" | 33.4 x 26.7 | 28 | 4.55 | ||

| Forged Nipple | 1/2" | 21.3 | 90 (length) | 3.75 | ASME B16.11 |

| 3/4" | 26.7 | 100 (length) | 3.90 | ||

| 1" | 33.4 | 110 (length) | 4.55 | ||

| Material | Grade | Pressure-Temperature Ratings (PSI) | Standard | ||||

|---|---|---|---|---|---|---|---|

| -20°F to 100°F | 200°F | 400°F | 600°F | 800°F | |||

| Stainless Steel | ASTM A403 WP304 | 150 | 125 | 110 | 95 | 80 | ASME B16.5 |

| ASTM A403 WP316 | 160 | 135 | 120 | 100 | 85 | ||

| ASTM A403 WP321 | 155 | 130 | 115 | 98 | 82 | ||

| ASTM A403 WP347 | 158 | 132 | 118 | 99 | 83 | ||

| Carbon Steel | ASTM A234 WPB | 140 | 120 | 100 | 85 | 70 | ASME B16.9 |

| ASTM A234 WPC | 145 | 123 | 103 | 87 | 72 | ||

| ASTM A420 WPL6 | 150 | 127 | 107 | 90 | 75 | ||

| ASTM A860 WPHY52 | 170 | 140 | 120 | 100 | 85 | ||

| Duplex Steel | ASTM A815 UNS S31803 | 180 | 150 | 130 | 110 | 95 | ASME B16.9 |

| ASTM A815 UNS S32205 | 190 | 160 | 140 | 115 | 100 | ||

| ASTM A815 UNS S32750 | 200 | 170 | 150 | 125 | 110 | ||

| Nickel Alloy | ASTM B366 UNS N06600 | 210 | 180 | 160 | 140 | 120 | ASME B16.9 |

| ASTM B366 UNS N08825 | 220 | 190 | 170 | 150 | 130 | ||

| ASTM B366 UNS N10276 | 230 | 200 | 180 | 160 | 140 | ||

| Material | Grade | Dimensional Tolerances (mm) | Wall Thickness Tolerances (%) | Standard | ||||

|---|---|---|---|---|---|---|---|---|

| OD (Outer Diameter) | ID (Inner Diameter) | Length | Min | Max | Average | |||

| Stainless Steel | ASTM A403 WP304 | ±0.5 | ±0.4 | ±1.0 | -12.5% | +12.5% | ±10% | ASME B16.9 |

| ASTM A403 WP316 | ±0.6 | ±0.5 | ±1.2 | -12.5% | +12.5% | ±10% | ||

| ASTM A403 WP321 | ±0.7 | ±0.6 | ±1.5 | -10% | +10% | ±8% | ||

| ASTM A403 WP347 | ±0.8 | ±0.7 | ±1.8 | -10% | +10% | ±8% | ||

| Carbon Steel | ASTM A234 WPB | ±0.5 | ±0.3 | ±1.0 | -12.5% | +12.5% | ±10% | ASME B16.9 |

| ASTM A234 WPC | ±0.6 | ±0.4 | ±1.2 | -12.5% | +12.5% | ±10% | ||

| ASTM A420 WPL6 | ±0.7 | ±0.5 | ±1.4 | -12.5% | +12.5% | ±10% | ||

| Duplex Steel | ASTM A815 UNS S31803 | ±0.6 | ±0.4 | ±1.2 | -10% | +10% | ±8% | ASME B16.9 |

| ASTM A815 UNS S32205 | ±0.7 | ±0.5 | ±1.5 | -10% | +10% | ±8% | ||

| ASTM A815 UNS S32750 | ±0.8 | ±0.6 | ±1.8 | -8% | +8% | ±7% | ||

| Nickel Alloy | ASTM B366 UNS N06600 | ±0.5 | ±0.3 | ±1.0 | -12.5% | +12.5% | ±10% | ASME B16.9 |

| ASTM B366 UNS N08825 | ±0.6 | ±0.4 | ±1.2 | -10% | +10% | ±8% | ||

| ASTM B366 UNS N10276 | ±0.7 | ±0.5 | ±1.4 | -8% | +8% | ±7% | ||

Forged pipe fittings are essential in high-pressure and high-temperature applications, offering superior strength, durability, and leak-proof connections. They are used in numerous critical industrial systems due to their compact structure and resistance to stress and corrosion.

Used in high-pressure pipelines and process lines for safe transportation of crude oil, gas, and fuels.

Ideal for systems handling aggressive chemicals, hydrocarbons, and steam under extreme conditions.

Used in boiler lines, superheaters, and turbine piping where high strength and heat resistance are essential.

Supports pipelines carrying corrosive chemicals and ensures reliable sealing in high-pressure applications.

Used in offshore and onshore marine systems, including ballast and bilge piping, due to corrosion resistance.

Integral in pressure-regulated systems for fluid transmission and control in machinery and automation.

Forged fittings ensure secure and compact piping connections in urban development and industrial projects.

Preferred for precision and reliability in mission-critical applications involving fuel and fluid systems.

The manufacturing process of forged fittings involves precision engineering, high-quality raw materials, and rigorous testing. This process ensures that the fittings deliver superior mechanical strength, pressure handling capability, and dimensional accuracy required for critical applications.

High-quality bars or billets of stainless steel, carbon steel, duplex, or special alloys are chosen based on the required chemical and mechanical properties.

The raw material is heated in a furnace to forging temperature and then forged under high pressure to shape into elbows, tees, unions, or other forged fitting forms.

Flash or excess material is trimmed, and rough machining is performed to bring the fittings close to their final dimensions.

Heat treatment such as annealing or normalizing is carried out to enhance strength, ductility, and corrosion resistance of the fittings.

CNC machines are used to finish the fittings to exact tolerances and surface finishes, ensuring proper thread cutting or socket depths.

Each forged fitting undergoes dimensional inspection, hydrostatic pressure testing, and non-destructive tests like ultrasonic or radiographic testing.

Fittings are cleaned, descaled, or coated with rust-preventive treatments such as pickling, passivation, or galvanization.

Final fittings are marked with size, material grade, and heat number, packed securely, and dispatched to ensure safe delivery.

A Forged Elbow is a high-pressure fitting used to change the direction of flow in piping systems. Available in 90-degree and 45-degree angles, these elbows are manufactured in socket weld and threaded end connections, ensuring leak-free operation under extreme pressure and temperature conditions. They are widely used in oil & gas, chemical processing, and power generation industries for compact, durable, and corrosion-resistant piping systems.

| Nominal Pipe Size (NPS) | OD (mm) | Center-to-End (90° Elbow) | Center-to-End (45° Elbow) | Socket Depth (mm) | Pressure Class |

|---|---|---|---|---|---|

| 1/2" | 21.3 | 33 | 25 | 10 | 3000# |

| 3/4" | 26.7 | 38 | 28 | 13 | 3000# |

| 1" | 33.4 | 44 | 32 | 13 | 3000# |

| 1 1/2" | 48.3 | 57 | 38 | 16 | 3000# |

| 2" | 60.3 | 64 | 44 | 19 | 3000# |

| 3" | 88.9 | 86 | 70 | 25 | 3000# |

A Forged Tee is a type of high-pressure pipe fitting used to combine or divide fluid flow. Available in both Equal Tee and Reducing Tee types, it is designed for socket weld and threaded end connections. Forged tees are used in a variety of applications where compact piping and high strength are required—especially in oil & gas, petrochemical, and power generation industries.

| Nominal Pipe Size (NPS) | OD (mm) | Center-to-End (Run) (A) | Center-to-End (Branch) (B) | Socket Depth (mm) | Pressure Class |

|---|---|---|---|---|---|

| 1/2" | 21.3 | 33 | 25 | 10 | 3000# |

| 3/4" | 26.7 | 38 | 28 | 13 | 3000# |

| 1" | 33.4 | 44 | 32 | 13 | 3000# |

| 1 1/2" | 48.3 | 57 | 38 | 16 | 3000# |

| 2" | 60.3 | 64 | 44 | 19 | 3000# |

| 3" | 88.9 | 86 | 70 | 25 | 3000# |

A Forged Cross is a four-way pipe fitting used to divide or combine flow in a piping system. It has one inlet and three outlets (or vice versa), all positioned at 90-degree angles. Available in both Equal Cross and Reducing Cross configurations, forged crosses are widely used in high-pressure and high-temperature applications. They are typically socket weld or threaded and are vital for process piping in refineries, petrochemical plants, and power stations.

| Nominal Pipe Size (NPS) | OD (mm) | Center-to-End (Run) (A) | Center-to-End (Branch) (B) | Socket Depth (mm) | Pressure Class |

|---|---|---|---|---|---|

| 1/2" | 21.3 | 33 | 25 | 10 | 3000# |

| 3/4" | 26.7 | 38 | 28 | 13 | 3000# |

| 1" | 33.4 | 44 | 32 | 13 | 3000# |

| 1 1/2" | 48.3 | 57 | 38 | 16 | 3000# |

| 2" | 60.3 | 64 | 44 | 19 | 3000# |

A Forged Union is a type of forged pipe fitting used to join two pipes while allowing easy future disconnection without cutting the pipe. It consists of three parts — a male end, a female end, and a nut — which securely compress and seal the connection. Unions are available in Socket Weld and Threaded forms and are widely used in applications requiring quick installation and removal, such as instrumentation, gas lines, and process piping.

| Nominal Pipe Size (NPS) | End Type | Outside Diameter (OD) | Length (Face to Face) | Pressure Rating |

|---|---|---|---|---|

| 1/2" | Socket Weld | 21.3 mm | 48 mm | 3000# |

| 3/4" | Threaded | 26.7 mm | 53 mm | 3000# |

| 1" | Socket Weld | 33.4 mm | 60 mm | 3000# |

| 1 1/2" | Threaded | 48.3 mm | 70 mm | 3000# |

| 2" | Socket Weld | 60.3 mm | 82 mm | 3000# |

A Swage Nipple is a type of forged fitting used to connect pipes of different diameters. It comes in two configurations: Concentric (aligned centerlines) and Eccentric (offset centerlines), allowing smooth transitions between different pipe sizes. Swage nipples are available with Plain Ends (PE), Beveled Ends (BE), or Threaded Ends (NPT/BSP), making them versatile for high-pressure and high-temperature piping systems.

| Size (Large End × Small End) | Type | Length (mm) | End Connection | Pressure Rating |

|---|---|---|---|---|

| 2" × 1" | Concentric | 120 mm | BE × NPT | 3000# |

| 3" × 1 1/2" | Eccentric | 150 mm | BE × NPT | 3000# |

| 4" × 2" | Concentric | 180 mm | PE × PE | 3000# |

| 6" × 3" | Eccentric | 200 mm | PE × NPT | 6000# |

| 8" × 4" | Concentric | 250 mm | BE × BE | 6000# |

A Forged Adaptor is a fitting used to connect pipes of different types or sizes, often transitioning between threaded and socket weld connections or male-to-female thread forms. These fittings allow for easy disassembly and reconnection of pipelines during maintenance. Adaptors are commonly used in systems where versatility, ease of installation, and reusability are crucial, such as in oil & gas, petrochemical, and instrumentation piping networks.

| Adaptor Type | Size (Inch) | Length (mm) | End Connection | Pressure Rating |

|---|---|---|---|---|

| Male × Female | 1/2" | 45 mm | NPT × NPT | 3000# |

| Male × Socket Weld | 3/4" | 50 mm | NPT × SW | 3000# |

| Threaded × Threaded | 1" | 58 mm | BSPT × BSPT | 6000# |

| Female × Socket Weld | 1 1/2" | 65 mm | NPT × SW | 3000# |

| Male × Male | 2" | 72 mm | NPT × NPT | 6000# |

A Forged Coupling is a short length of pipe used to connect two pipes or fittings in a straight line. Available in Full Coupling (connects two pipes) and Half Coupling (connects a pipe to a fitting or branch), these fittings are vital for assembling and disassembling piping systems. Couplings are manufactured in both Threaded and Socket Weld forms and are widely used in industries where high-pressure and leak-proof connections are required.

| Coupling Type | Size (Inch) | Length (mm) | End Connection | Pressure Rating |

|---|---|---|---|---|

| Full Coupling | 1/2" | 32 mm | Socket Weld | 3000# |

| Half Coupling | 3/4" | 26 mm | Threaded (NPT) | 3000# |

| Full Coupling | 1" | 41 mm | Socket Weld | 6000# |

| Half Coupling | 1 1/2" | 38 mm | Threaded (BSPT) | 6000# |

| Full Coupling | 2" | 51 mm | Socket Weld | 3000# |

A Forged Pipe Cap is a type of forged fitting used to terminate the end of a pipe. It provides a secure closure to piping systems and prevents leakage, debris ingress, or damage to open pipe ends. These caps are typically installed using socket weld or threaded connections and are widely used in high-pressure, high-temperature applications across industries such as oil & gas, chemical, power generation, and petrochemical plants.

| Size (Inch) | Outer Diameter (OD) | Height (mm) | End Connection | Pressure Rating |

|---|---|---|---|---|

| 1/2" | 21.3 mm | 25 mm | Socket Weld | 3000# |

| 3/4" | 26.7 mm | 28 mm | Threaded (NPT) | 3000# |

| 1" | 33.4 mm | 32 mm | Socket Weld | 6000# |

| 1 1/2" | 48.3 mm | 38 mm | Threaded | 6000# |

| 2" | 60.3 mm | 44 mm | Socket Weld | 3000# |