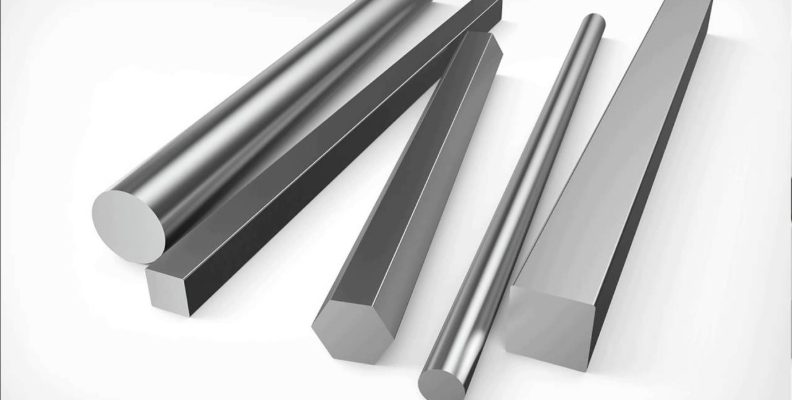

ARK Stainless Inc. offers a premium selection of Tantalum Bars & Rods, crafted to meet the most demanding requirements in highly corrosive and high-temperature industrial environments. Known for their exceptional resistance to a wide range of aggressive chemicals, these bars are extensively used in applications involving acid processing, high-purity equipment, electronics, and aerospace engineering.

Our product portfolio includes grades such as Tantalum R05200 and Tantalum R05400 in round bar and rod forms. Tantalum R05200 is a high-purity metal known for its ductility and excellent fabrication characteristics, while Tantalum R05400 contains controlled levels of oxygen, providing improved strength without compromising corrosion resistance—making both grades suitable for severe chemical service.

These bars are manufactured under strict quality control procedures in accordance with ASTM B365 / ASME SB365, ensuring outstanding reliability and consistency. Tantalum Bars & Rods exhibit high melting points, excellent formability, and resistance to corrosion by acids like sulfuric, nitric, and hydrochloric acid, making them ideal for reactor vessels, heat exchangers, and pharmaceutical equipment.

Each batch of Tantalum R05200/R05400 bars undergoes comprehensive testing and inspection, including chemical composition analysis, mechanical testing, ultrasonic inspection, and Positive Material Identification (PMI). Documentation such as Mill Test Certificates, EN 10204 3.1 reports, and Third-Party Inspection Certificates are provided to ensure full traceability and compliance with international quality standards.

| Tantalum | C | O | N | H | Nb | Fe | Ti | W | Mo | Si | Ni | Ta |

| R05200 | 0.010 | 0.015 | 0.010 | 0.0015 | 0.100 | 0.010 | 0.010 | 0.050 | 0.020 | 0.005 | 0.010 | Remainder |

| Tantalum Alloy Rods & Bars Mechanical Property | ||||

| Grade | Tensile strength ">, psi (MPa), ≥ | Yield strength ">, psi (MPa), ≥ | Elongation in 1 inch gage length, %, ≥ | |

| RO5400 | 25000 (172) | 15000 (103) | 25 | |