ARK Stainless Inc. is a trusted Manufacturer and Exporter of high-quality Pipes & Tubes, engineered to meet the highest industry standards. Headquartered in Mumbai, India, we specialize in producing precision-engineered seamless and welded pipes & tubes that offer exceptional strength, durability, and performance for a wide range of industrial applications.

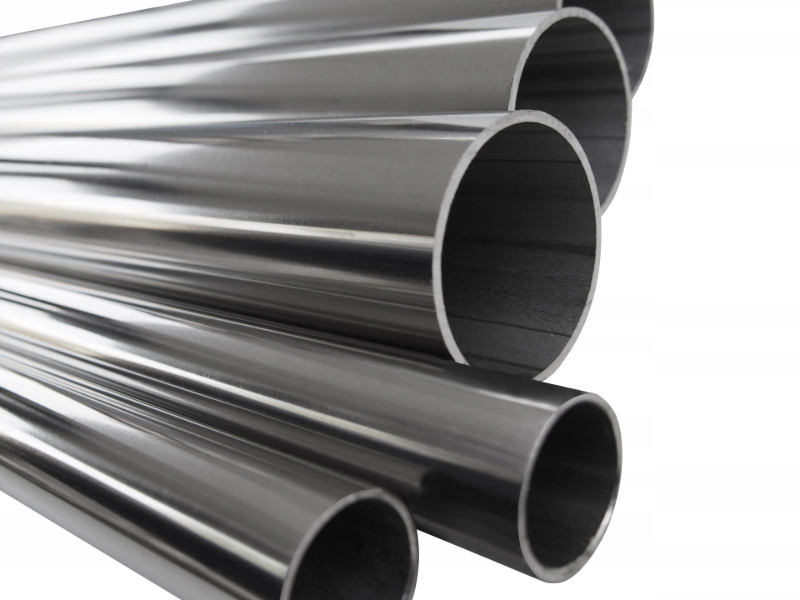

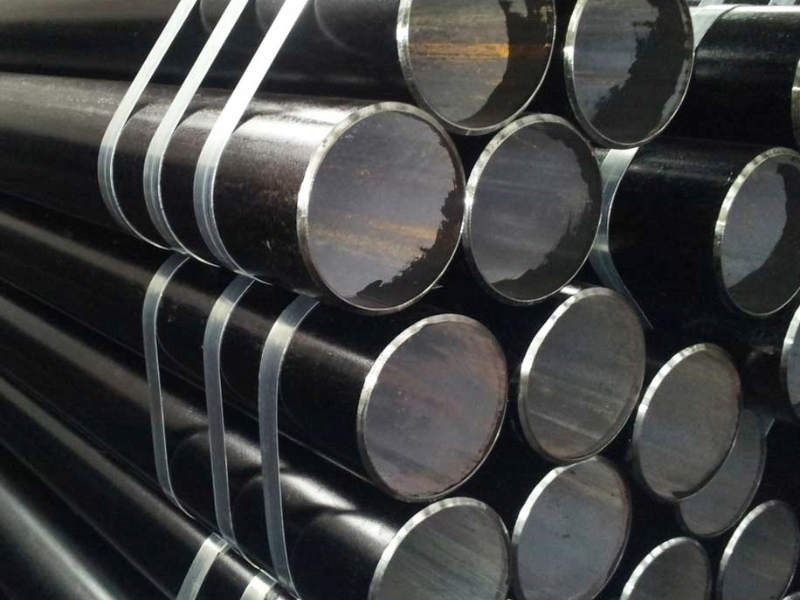

Our extensive inventory includes both black pipes and bright pipes, available in various grades, sizes, and specifications to suit diverse industrial needs. Whether you require Seamless Pipes, Seamless Tubes, Welded Pipes, Welded Tubes, EFW Pipes, or ERW Pipes & Tubes, we offer solutions that meet international quality standards, ensuring high performance under extreme conditions.

Manufactured using premium-quality materials, including Stainless Steel, Carbon Steel, Duplex & Super Duplex Steel, Alloy Steel, Nickel Alloys, Titanium, and Cupro-Nickel, our pipes and tubes are designed for superior corrosion resistance, high tensile strength, and excellent mechanical properties. Each product undergoes strict quality control and non-destructive testing (NDT) to ensure precision, reliability, and longevity.

Designed for critical industrial applications, our pipes and tubes support industries such as Oil & Gas, Construction, Chemical Processing, Power Generation, Aerospace, Automotive, Pharmaceuticals, and Heat Exchangers. Whether used for structural frameworks, fluid transportation, instrumentation, or heavy-duty engineering projects, our products offer secure, leak-proof, and high-performance solutions.

At ARK Stainless Inc., we also provide customization options in terms of dimensions, finishes (Matte, Mirror, Silver), and material grades to meet specific project requirements. Our commitment to innovation, quality, and excellence ensures that our pipes and tubes contribute to enhanced efficiency, reduced maintenance costs, and long-term reliability in industrial applications worldwide.

| Material | Standard | Available Grades | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| Stainless Steel | ASTM A312 / A213 | 304 | 304L | 304H | 309 | 310 | 310S | 316 | 316L | 316Ti | 317L |

| 321 | 321H | 347 | 347H | 410 | 446 | 904L | |||||

| Duplex / Super Duplex | ASTM A790 / A928 | Duplex S31803 / S32205 | Super Duplex S32750 / S32760 | ||||||||

| Nickel Alloys | ASTM B161 / B163 | Nickel 200 | Nickel 201 | Inconel 600 | Inconel 601 | Inconel 625 | Inconel 718 | Incoloy 800 | Incoloy 800HT | Incoloy 825 | |

| Alloy Steel | ASTM A335 / A213 | P5 | P9 | P11 | P12 | P22 | P91 | P92 | |||

| Titanium | ASTM B338 | Gr 1 | Gr 2 | Gr 5 | Gr 9 | ||||||

| Carbon Steel | ASTM A106 / A53 / API 5L | Seamless | ERW | SAW | LSAW | HSAW | API 5L | ||||

| Copper Nickel | ASTM B466 / B467 | CuNi 70/30 | CuNi 90/10 | ||||||||

| Other Alloys | - | SMO 254 | Alloy 28 | 253 MA (S30815) | Alloy 20 | Hastelloy | Aluminium | ||||

| Type | Material | Grades | Size Range | Wall Thickness | Standards |

|---|---|---|---|---|---|

| Seamless, Welded, EFW, ERW | Stainless Steel | SS 304/304L/304H | ½” - 24” | 1.65mm - 20mm | ASTM A312, A213, A249 |

| SS 309/310/310S | |||||

| SS 316/316L/316Ti | |||||

| SS 317/317L | |||||

| SS 321/321H | |||||

| SS 347/347H | |||||

| SS 410 | |||||

| SS 446 | |||||

| SS 904L | |||||

| Seamless, Welded | Duplex / Super Duplex | Duplex S31803 / S32205 | ½” - 24” | 1.65mm - 20mm | ASTM A790, A928 |

| Super Duplex S32750 / S32760 | |||||

| Seamless, Welded | Inconel / Incoloy | Inconel 600/601/625/718 | ½” - 16” | 1.24mm - 12.7mm | ASTM B163, B167 |

| Incoloy 800/800HT/825 | |||||

| Seamless, Welded | Monel | Monel 400/K500 | ½” - 14” | 1.24mm - 10mm | ASTM B165, B725 |

| Seamless, Welded | Nickel | Nickel 200/201 | ½” - 12” | 1.24mm - 10mm | ASTM B161, B725 |

| Seamless, Welded | Hastelloy | Hastelloy C22, C276 | ½” - 12” | 1.24mm - 10mm | ASTM B622, B619 |

| Seamless, Welded | Alloy 20 | Alloy 20 | ½” - 12” | 1.24mm - 10mm | ASTM B729, B464 |

| Seamless | Alloy Steel | Alloy Steel P5 | ½” - 24” | 2mm - 20mm | ASTM A335 |

| Alloy Steel P9 | |||||

| Alloy Steel P11 | |||||

| Alloy Steel P12 | |||||

| Alloy Steel P22 | |||||

| Alloy Steel P91 |

| Pipe Type | Material & Grade | Dimensions (mm) | Wall Thickness (SCH 40) | Standard | |

|---|---|---|---|---|---|

| Outer Diameter (OD) | Length (L) | ||||

| Seamless Pipe | SS 304/304L/304H | 21.3 | 6000 | 2.77 | ASTM A312 / A213 |

| SS 316/316L/316Ti | 26.7 | 6000 | 2.87 | ||

| SS 321/321H | 33.4 | 6000 | 3.38 | ||

| Welded Pipe | Duplex S31803/S32205 | 42.4 | 6000 | 3.56 | ASTM A790 / A358 |

| Super Duplex S32750/S32760 | 48.3 | 6000 | 3.68 | ||

| Nickel 200/201 | 60.3 | 6000 | 4.78 | ||

| ERW Tube | Alloy Steel P5 | 73.0 | 6000 | 5.16 | ASTM A335 / A691 |

| Alloy Steel P22 | 88.9 | 6000 | 5.49 | ||

| Alloy Steel P91 | 114.3 | 6000 | 6.35 | ||

| EFW Pipe | Inconel 600 | 141.3 | 6000 | 7.11 | ASTM B163 / B705 |

| Monel 400 | 168.3 | 6000 | 7.92 | ||

| Hastelloy C22 | 219.1 | 6000 | 8.74 | ||

| Material | Grade | Pressure-Temperature Ratings (PSI) | Standard | ||||

|---|---|---|---|---|---|---|---|

| -20°F to 100°F | 200°F | 400°F | 600°F | 800°F | |||

| Stainless Steel | SS 304/304L/304H | 160 | 135 | 120 | 100 | 85 | ASME B36.19 |

| SS 316/316L/316Ti | 170 | 140 | 125 | 105 | 90 | ||

| SS 321/321H | 165 | 138 | 123 | 102 | 88 | ||

| Duplex Steel | Duplex S31803/S32205 | 190 | 160 | 140 | 115 | 100 | ASME B36.19 |

| Super Duplex S32750/S32760 | 200 | 170 | 150 | 125 | 110 | ||

| Nickel Alloy | Inconel 600/625 | 210 | 180 | 160 | 140 | 120 | ASME B36.19 |

| Monel 400/K500 | 220 | 190 | 170 | 150 | 130 | ||

| Carbon Steel | API 5L Line Pipes | 150 | 125 | 110 | 95 | 80 | ASME B36.10 |

| Alloy Steel | Alloy Steel P5/P9 | 180 | 150 | 130 | 110 | 95 | ASME B36.10 |

| Aluminium Alloy | Aluminium Pipes | 120 | 100 | 85 | 70 | 60 | ASME B36.19 |

| Material | Grade | Dimensional Tolerances (mm) | Wall Thickness Tolerances (%) | Standard | ||||

|---|---|---|---|---|---|---|---|---|

| OD (Outer Diameter) | ID (Inner Diameter) | Length | Min | Max | Average | |||

| Stainless Steel | SS 304/304L/304H | ±0.5 | ±0.4 | ±1.0 | -12.5% | +12.5% | ±10% | ASTM A312 |

| SS 316/316L/316Ti | ±0.6 | ±0.5 | ±1.2 | -12.5% | +12.5% | ±10% | ||

| SS 321/321H | ±0.7 | ±0.6 | ±1.5 | -10% | +10% | ±8% | ||

| Duplex / Super Duplex | S31803 / S32205 | ±0.6 | ±0.4 | ±1.2 | -10% | +10% | ±8% | ASTM A790 |

| S32750 / S32760 | ±0.8 | ±0.6 | ±1.8 | -8% | +8% | ±7% | ||

| Nickel Alloy | Nickel 200/201 | ±0.5 | ±0.3 | ±1.0 | -12.5% | +12.5% | ±10% | ASTM B161 |

| Monel 400/K500 | ±0.6 | ±0.4 | ±1.2 | -10% | +10% | ±8% | ||

| Hastelloy | Hastelloy Pipes & Tubes | ±0.7 | ±0.5 | ±1.4 | -8% | +8% | ±7% | ASTM B622 |

| Carbon Steel | API 5L Line Pipes | ±0.5 | ±0.3 | ±1.0 | -12.5% | +12.5% | ±10% | API 5L |

| Aluminium | Aluminium Alloy Pipes | ±0.6 | ±0.4 | ±1.2 | -10% | +10% | ±8% | ASTM B241 |

Pipes and tubes are essential components in various industries due to their durability, strength, and versatility. Some of the key applications include:

Used for transporting crude oil, natural gas, and petroleum products in refineries and offshore rigs.

Essential for transporting chemicals, gases, and other hazardous materials safely.

Used in high-pressure steam pipelines for thermal, nuclear, and hydroelectric power plants.

Applied in sewage systems, desalination plants, and water supply networks.

Used for transporting purified water and medical gases in cleanroom environments.

Stainless steel pipes ensure hygienic processing and transportation of liquids and gases.

Used for seawater pipelines, ballast systems, and engine exhaust systems.

Integral for building structures, bridges, and underground pipelines in urban areas.

The manufacturing of pipes & tubes involves a series of precise steps to ensure durability, strength, and compliance with industry standards. This includes raw material selection, forming, welding (if applicable), heat treatment, finishing, and testing.

High-quality raw materials like stainless steel, carbon steel, alloy steel, and other metals are selected based on application requirements.

For seamless pipes, a solid billet is heated and pierced to create a hollow tube. For welded pipes, metal sheets or coils are rolled and welded into shape.

The edges of rolled sheets are welded using Electric Resistance Welding (ERW) or Submerged Arc Welding (SAW) techniques and then sized to precise dimensions.

Pipes undergo heat treatment like annealing, normalizing, or quenching & tempering to enhance mechanical properties and remove stresses.

Pipes are drawn through dies for precise dimensions and improved surface finish. Additional treatments like polishing or coating may be applied.

Pipes are inspected through non-destructive testing (NDT), hydrostatic testing, and ultrasonic testing to meet industry standards.

Pipes are treated with pickling & passivation, galvanization, or epoxy coatings for enhanced corrosion resistance.

Pipes and tubes are securely packed, labeled with specifications, and dispatched for safe transportation and delivery.

Seamless pipes are manufactured without a welded seam, making them stronger and more reliable for high-pressure applications. These pipes are produced through a hot rolling or cold drawing process, ensuring uniformity in shape and dimensions. They are widely used in industries such as oil & gas, petrochemicals, power plants, and marine applications due to their superior strength, corrosion resistance, and ability to withstand extreme conditions.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Wall Thickness (SCH 40) | Wall Thickness (SCH 80) | Length (Standard) |

|---|---|---|---|---|

| 1/2" | 21.3 mm | 2.77 mm | 3.73 mm | 6m / 12m |

| 3/4" | 26.7 mm | 2.87 mm | 3.91 mm | 6m / 12m |

| 1" | 33.4 mm | 3.38 mm | 4.55 mm | 6m / 12m |

| 2" | 60.3 mm | 3.91 mm | 5.54 mm | 6m / 12m |

| 4" | 114.3 mm | 6.02 mm | 8.56 mm | 6m / 12m |

| 6" | 168.3 mm | 7.11 mm | 10.97 mm | 6m / 12m |

| 8" | 219.1 mm | 8.18 mm | 12.70 mm | 6m / 12m |

Seamless tubes are cylindrical hollow sections manufactured without any welding, ensuring superior strength and uniformity. These tubes are widely used in critical applications requiring high precision, pressure resistance, and corrosion resistance, such as in automotive, aerospace, oil & gas, and mechanical industries. Seamless tubes are available in various materials, including stainless steel, carbon steel, and alloy steel, to meet different industrial needs.

| Nominal Tube Size (NTS) | Outside Diameter (OD) | Wall Thickness (Light Gauge) | Wall Thickness (Heavy Gauge) | Length (Standard) |

|---|---|---|---|---|

| 1/4" | 6.35 mm | 0.89 mm | 1.65 mm | 6m / Custom |

| 3/8" | 9.53 mm | 1.24 mm | 2.11 mm | 6m / Custom |

| 1/2" | 12.70 mm | 1.65 mm | 2.77 mm | 6m / Custom |

| 3/4" | 19.05 mm | 2.11 mm | 3.73 mm | 6m / Custom |

| 1" | 25.40 mm | 2.77 mm | 4.55 mm | 6m / Custom |

| 1 1/2" | 38.10 mm | 3.38 mm | 5.08 mm | 6m / Custom |

| 2" | 50.80 mm | 3.91 mm | 5.54 mm | 6m / Custom |

Welded pipes are manufactured by rolling a metal sheet and welding the seam to create a hollow cylindrical shape. They are cost-effective, versatile, and suitable for various industrial applications. These pipes are commonly used in structural, plumbing, and fluid transportation industries due to their availability in different sizes, materials, and wall thicknesses. Welded pipes offer excellent corrosion resistance and mechanical properties when produced with advanced welding techniques.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Wall Thickness (SCH 40) | Wall Thickness (SCH 80) | Length (Standard) |

|---|---|---|---|---|

| 1/2" | 21.3 mm | 2.77 mm | 3.73 mm | 6m / 12m |

| 3/4" | 26.7 mm | 2.87 mm | 3.91 mm | 6m / 12m |

| 1" | 33.4 mm | 3.38 mm | 4.55 mm | 6m / 12m |

| 2" | 60.3 mm | 3.91 mm | 5.54 mm | 6m / 12m |

| 4" | 114.3 mm | 6.02 mm | 8.56 mm | 6m / 12m |

| 6" | 168.3 mm | 7.11 mm | 10.97 mm | 6m / 12m |

| 8" | 219.1 mm | 8.18 mm | 12.70 mm | 6m / 12m |

Welded tubes are produced by rolling and welding metal sheets into cylindrical shapes, followed by welding along the seam. These tubes are widely used in automotive, construction, heat exchangers, and fluid transport applications due to their cost-effectiveness and availability in various sizes and materials. Advanced welding techniques ensure structural integrity and enhanced performance in different environmental conditions.

| Nominal Tube Size (NTS) | Outside Diameter (OD) | Wall Thickness (Light Gauge) | Wall Thickness (Heavy Gauge) | Length (Standard) |

|---|---|---|---|---|

| 1/4" | 6.35 mm | 0.89 mm | 1.65 mm | 6m / Custom |

| 3/8" | 9.53 mm | 1.24 mm | 2.11 mm | 6m / Custom |

| 1/2" | 12.70 mm | 1.65 mm | 2.77 mm | 6m / Custom |

| 3/4" | 19.05 mm | 2.11 mm | 3.73 mm | 6m / Custom |

| 1" | 25.40 mm | 2.77 mm | 4.55 mm | 6m / Custom |

| 1 1/2" | 38.10 mm | 3.38 mm | 5.08 mm | 6m / Custom |

| 2" | 50.80 mm | 3.91 mm | 5.54 mm | 6m / Custom |

Electric Fusion Welded (EFW) pipes are manufactured by rolling a metal plate and using electrical current to heat and fuse the edges. These pipes are widely used in industries such as oil & gas, water pipelines, structural applications, and high-temperature environments. EFW pipes are known for their excellent weld integrity, high mechanical strength, and suitability for large-diameter applications.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Wall Thickness (SCH 40) | Wall Thickness (SCH 80) | Length (Standard) |

|---|---|---|---|---|

| 2" | 60.3 mm | 3.91 mm | 5.54 mm | 6m / 12m |

| 4" | 114.3 mm | 6.02 mm | 8.56 mm | 6m / 12m |

| 6" | 168.3 mm | 7.11 mm | 10.97 mm | 6m / 12m |

| 8" | 219.1 mm | 8.18 mm | 12.70 mm | 6m / 12m |

| 10" | 273.1 mm | 9.27 mm | 15.09 mm | 6m / 12m |

| 12" | 323.9 mm | 10.31 mm | 17.48 mm | 6m / 12m |

| 16" | 406.4 mm | 12.70 mm | 21.44 mm | 6m / 12m |

Electric Resistance Welded (ERW) pipes and tubes are manufactured by cold-forming a steel strip into a cylindrical shape and fusing the edges using electrical resistance. ERW pipes and tubes are widely used in industries such as oil & gas, structural applications, water pipelines, and automotive components due to their high strength, uniform thickness, and cost-effectiveness.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Wall Thickness (SCH 40) | Wall Thickness (SCH 80) | Length (Standard) |

|---|---|---|---|---|

| 1/2" | 21.3 mm | 2.77 mm | 3.73 mm | 6m / 12m |

| 3/4" | 26.7 mm | 2.87 mm | 3.91 mm | 6m / 12m |

| 1" | 33.4 mm | 3.38 mm | 4.55 mm | 6m / 12m |

| 2" | 60.3 mm | 3.91 mm | 5.54 mm | 6m / 12m |

| 4" | 114.3 mm | 6.02 mm | 8.56 mm | 6m / 12m |

| 6" | 168.3 mm | 7.11 mm | 10.97 mm | 6m / 12m |

| 8" | 219.1 mm | 8.18 mm | 12.70 mm | 6m / 12m |