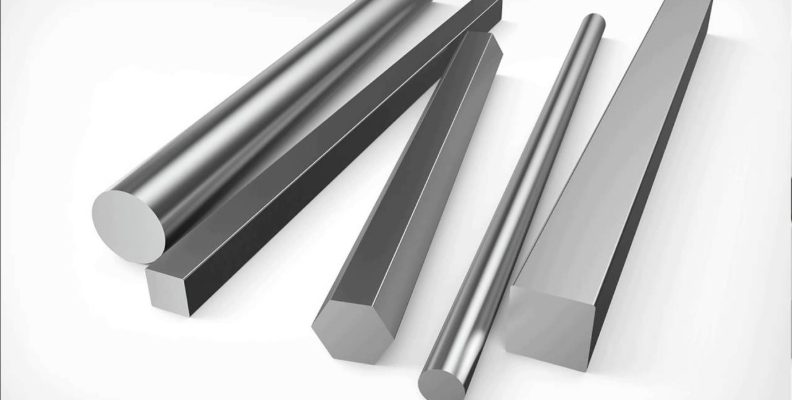

Nickel alloys, particularly Nickel 200 and Nickel 201, are renowned for their exceptional corrosion resistance, excellent mechanical properties, and superior thermal and electrical conductivity. ARK Stainless Inc. offers premium Nickel Alloy Round Bars & Rods designed to meet the rigorous demands of critical industrial sectors.

These bars and rods find extensive applications in chemical processing, aerospace, marine environments, electrical components, and food processing industries. The high purity and quality of Nickel 200/201 provide outstanding resistance to caustic alkalis, neutral and alkaline salt solutions, dry gases, and other aggressive media, ensuring reliability and longevity in severe service conditions.

Manufactured to exacting standards including ASTM B160 / ASME SB160, our Nickel Alloy Bars and Rods are available in hot-rolled, cold-drawn, and annealed conditions. These products are offered in various diameters and lengths, with customizable finishes and tolerances to match specific project requirements.

ARK Stainless Inc. ensures that all Nickel Alloy Bars and Rods undergo thorough quality assurance processes including positive material identification (PMI), mechanical and corrosion testing, ultrasonic examination, and third-party inspections. This guarantees compliance with international standards and complete customer satisfaction for demanding industrial applications.

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Nickel 200/201 Round Bars & Rods are extensively utilized in industries requiring superior corrosion resistance, excellent mechanical strength, and outstanding thermal and electrical conductivity. These bars and rods are widely used in chemical processing, marine engineering, aerospace, electronics, and food processing industries where exposure to harsh and corrosive environments is common.

Nickel 200 is a commercially pure wrought nickel known for its excellent resistance to alkalis and good mechanical properties. Nickel 201, the low-carbon variant, offers enhanced resistance to graphitization and improved stability at elevated temperatures, making it suitable for demanding high-temperature applications. Both grades conform to international standards such as ASTM B160 / ASME SB160 and are manufactured to strict dimensional and quality standards.

ARK Stainless Inc. produces Nickel 200/201 Round Bars & Rods in various diameters and lengths, with finishes suitable for machining, forming, and welding. These products are renowned for their ductility, weldability, and excellent workability, making them ideal for use in structural components, fasteners, shafts, and chemical handling equipment.

Our Nickel Bars and Rods undergo rigorous quality testing, including chemical composition analysis, positive material identification (PMI), mechanical testing, ultrasonic examination, and third-party inspections. Comprehensive documentation such as Mill Test Certificates (MTC), EN 10204 3.1 reports, and full traceability are provided to ensure compliance with international standards and customer specifications.

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| Nickel 200 | N02200 | 2.4066 | NW 2200 | Ni 99.2 |

| Nickel 201 | N02201 | 2.4068 | NW 2201 | LC-Ni 99 |