ARK Stainless Inc. is a reliable manufacturer and supplier of high-quality Copper Nickel Bars, offering excellent mechanical strength, corrosion resistance, and long-term durability. These bars are specifically designed for use in marine, offshore, chemical, and industrial applications where resistance to seawater and aggressive environments is essential.

We supply Copper Nickel Bars in two primary grades – 70/30 (C71500) and 90/10 (C70600). Copper Nickel 70/30 offers superior strength and enhanced corrosion resistance, particularly in high-velocity seawater and polluted marine atmospheres. Copper Nickel 90/10, with its excellent fabricability and thermal conductivity, is widely used in condenser and heat exchanger systems, shipbuilding, piping, and seawater systems.

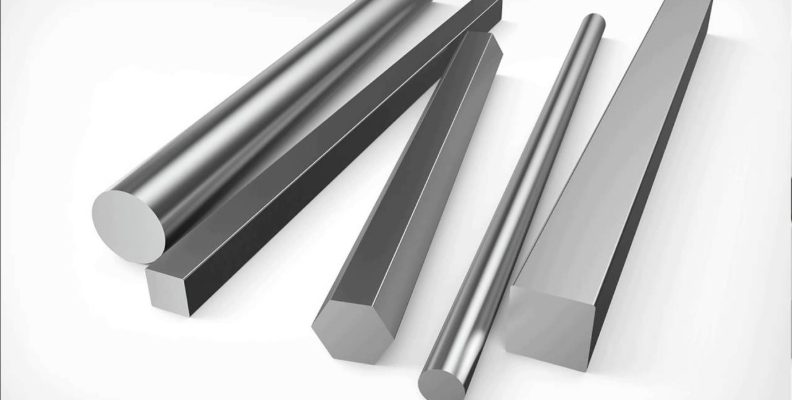

Our Copper Nickel Round Bars are available in various sizes, lengths, and finishes including hot rolled, cold drawn, and polished variants. These bars are produced in strict accordance with global quality standards such as ASTM B151 and ASME SB151, ensuring high dimensional accuracy, smooth surface finishes, and excellent workability. Every batch undergoes rigorous quality checks including mechanical testing, chemical composition verification, and ultrasonic inspection.

At ARK Stainless Inc., our commitment to precision, performance, and international compliance makes our Copper Nickel Bars the preferred choice for critical engineering and fabrication projects. Whether you're building marine hardware, offshore piping systems, or industrial condensers, our copper nickel bars deliver reliability and performance in the most demanding environments.

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

|---|---|---|---|---|---|---|

| Copper Nickel 90/10 (C70600) | 88.6 min | 1.0 max | 0.05 max | 9.0 – 11.0 | 1.8 max | 1.0 max |

| Copper Nickel 70/30 (C71500) | Balance | 1.0 max | 0.05 max | 29.0 – 33.0 | 0.4 – 1.0 | 1.0 max |

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Hardness (Rockwell) | Density (g/cm³) | Melting Point (°C) |

|---|---|---|---|---|---|---|---|

| Copper Nickel 90/10 (C70600) | 275 – 380 | 105 – 140 | 30 – 45 | 60 – 100 | F60 – F75 | 8.94 | 1100 – 1145 |

| Copper Nickel 70/30 (C71500) | 310 – 500 | 110 – 175 | 20 – 40 | 80 – 130 | F70 – F90 | 8.94 | 1170 – 1240 |

Copper Nickel 70/30 Bars are widely used in demanding marine and industrial environments due to their exceptional resistance to seawater corrosion, stress cracking, and erosion. These bars are highly suitable for applications such as offshore oil platforms, desalination plants, shipbuilding, heat exchangers, and condenser systems where durability and long-term reliability are crucial.

Engineered using premium-grade C71500 alloy, Copper Nickel 70/30 Bars offer excellent mechanical strength, thermal stability, and weldability. The addition of iron and manganese enhances their overall corrosion resistance and mechanical properties in saltwater and brackish water environments. These bars maintain strength and integrity even under high pressure and temperature fluctuations.

Available in a range of diameters, lengths, and finishes such as hot rolled, cold drawn, and centerless ground, our Copper Nickel 70/30 Bars are manufactured in strict adherence to global standards including ASTM B151 / B122 / B466. Each product undergoes rigorous quality checks including chemical analysis, mechanical property testing, and non-destructive testing to ensure optimal performance in service.

ARK Stainless Inc. ensures safe and secure packaging using wooden crates, plastic wraps, or customized methods as per client specifications. Our bars are delivered with full documentation, including test certificates and compliance reports, making them a trusted choice for critical marine and industrial components.

| STANDARD | UNS | WNR. |

|---|---|---|

| Copper Nickel 70/30 | C71500 | 2.0882 |

Copper Nickel 90/10 Bars are highly valued for their exceptional resistance to seawater corrosion, biofouling, and stress corrosion cracking. Made from the C70600 alloy, these bars are a preferred choice in industries such as marine engineering, desalination, shipbuilding, offshore oil rigs, and heat exchanger systems.

Known for excellent weldability and thermal conductivity, Copper Nickel 90/10 Bars offer a unique combination of mechanical strength and corrosion resistance in both saltwater and polluted environments. The presence of 10% nickel enhances the material’s strength and seawater performance while ensuring excellent formability and durability.

These bars are produced in multiple forms including round, hex, square, and flat bars, with surface finishes like polished, bright, or centerless ground. Manufactured to comply with ASTM B151 / B122 / B466 and equivalent international standards, each bar undergoes strict quality control checks such as chemical analysis, mechanical property validation, and non-destructive testing for assured reliability.

ARK Stainless Inc. ensures safe packaging and delivery with options including wooden crates, plastic wrapping, or steel strapped bundles, customized per client needs. Complete documentation including mill test certificates and third-party inspection reports are provided to guarantee full traceability and product authenticity.

| STANDARD | UNS | WNR. |

|---|---|---|

| Copper Nickel 90/10 | C70600 | 2.0872 |