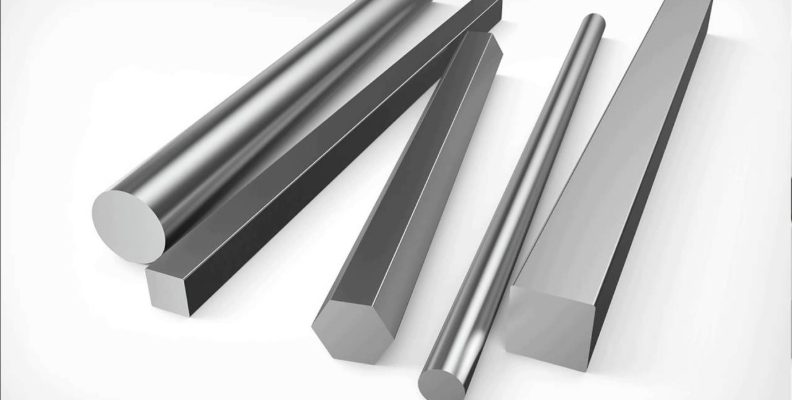

ARK Stainless Inc. offers a comprehensive range of premium-grade Alloy 20 Bars & Rods, engineered for superior resistance to acid attacks, especially sulfuric acid. These bars are widely used in aggressive chemical environments due to their excellent corrosion resistance, durability, and strength.

Alloy 20, also referred to as Carpenter 20 or UNS N08020, is an austenitic nickel-iron-chromium alloy with additions of copper and molybdenum. It is ideal for applications in chemical processing, pharmaceuticals, food and beverage, marine, and petrochemical industries. The alloy demonstrates outstanding resistance to pitting, crevice corrosion, and chloride stress corrosion cracking.

Manufactured in accordance with stringent industry standards such as ASTM B473 / ASME SB473, our Alloy 20 bars & rods are known for their machinability, weldability, and consistent mechanical performance. These bars are supplied in various sizes, forms, and finishes to meet the specific needs of customers across industries.

All Alloy 20 bars undergo rigorous quality checks including chemical analysis, mechanical testing, PMI testing, and non-destructive testing. We also provide full traceability and documentation including Mill Test Certificates, EN 10204 3.1 certificates, and Third-Party Inspection reports to meet global compliance and quality requirements.

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Fe | Mo | P |

|---|---|---|---|---|---|---|---|---|---|---|

| Alloy 20 | 0.07 max | 2.00 max | 1.00 max | 0.035 max | 3.00 – 4.00 | 32.00 – 38.00 | 19.00 – 21.00 | 29.85 min* | 2.00 – 3.00 | 0.045 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi - 35,000, MPa - 241 | 30 % |

| STANDARD | UNS | WNR. | EN | AFNOR |

|---|---|---|---|---|

| Alloy 20 | N08020 | 2.4660 | NiCr20CuMo | Z2NCUD31-20AZ |