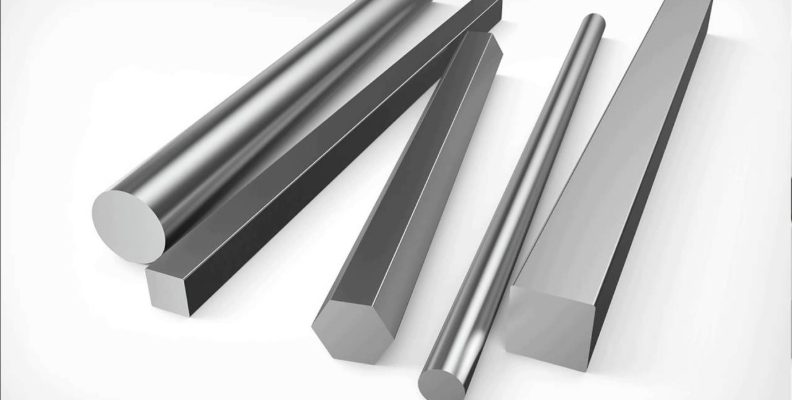

ARK Stainless Inc. supplies a wide range of high-quality Hastelloy Bars & Rods, designed to deliver exceptional strength and corrosion resistance in the most demanding industrial environments. These bars are extensively utilized across sectors such as chemical processing, aerospace, marine, and power generation where resistance to extreme temperatures and aggressive chemicals is essential.

Our stock includes premium grades like Hastelloy C22 and Hastelloy C276 in round bar and rod forms. Hastelloy C22 offers superior resistance to oxidizing and reducing agents, making it ideal for applications exposed to a wide range of chemical conditions. Hastelloy C276 is highly regarded for its outstanding resistance to wet chlorine, strong oxidizers, and highly corrosive acid environments, ensuring longevity and reliability in critical components.

Manufactured under stringent quality controls and conforming to international standards such as ASTM B574 / ASME SB574, our Hastelloy Bars & Rods offer excellent machinability, weldability, and mechanical strength. These bars are suitable for precision machining and fabrication into parts like shafts, fasteners, and structural components requiring resistance to stress corrosion cracking and pitting.

To guarantee optimum quality, all Hastelloy C22/C276 bars undergo comprehensive testing including chemical analysis, tensile and hardness testing, PMI verification, and non-destructive inspections. We provide full certification packages such as Mill Test Certificates, EN 10204 3.1 certification, and third-party inspection reports to ensure complete traceability and compliance with customer requirements.

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C22 | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 max | 20.00 - 22.50 | 2.00 - 6.00 | 12.50 - 14.50 | 0.02 max |

| Hastelloy C276 | 0.01 max | 1.0 max | 0.08 max | 2.50 max | Balance | 14.5-16.5 | 4-7 | 15-17 | 0.04 max | 0.04 max |

| Grade | Tensile (ksi) | .2% Yield (ksi) | Elongation % | Hardness (HRb) |

|---|---|---|---|---|

| C22 | 115 | 55 | 60 | 89 |

| C276 | 110 | 52.6 | 62 | - |

Hastelloy C22/C276 Bars & Rods are precisely manufactured to offer outstanding mechanical strength and exceptional corrosion resistance in highly demanding industrial environments. These bars are widely used in chemical processing, aerospace, marine, and power generation sectors, where durability against oxidizing and reducing agents, acids, and extreme temperatures is critical.

Available in round bar and rod forms, our Hastelloy C22 and C276 bars are suitable for machining and fabrication into critical components such as shafts, fasteners, structural parts, and machinery exposed to corrosive and high-stress conditions.

Manufactured in compliance with stringent international standards like ASTM B574 / ASME SB574, these bars exhibit excellent weldability, high tensile strength, and resistance to stress corrosion cracking, pitting, and crevice corrosion.

At ARK Stainless Inc., every batch of Hastelloy C22/C276 Bars undergoes rigorous quality assurance including chemical composition verification, mechanical testing, PMI analysis, and non-destructive examination to ensure consistent performance and reliability. Comprehensive documentation such as Mill Test Certificates, EN 10204 3.1 certification, and third-party inspection reports are provided with each shipment to guarantee full traceability and quality compliance.

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| Hastelloy C22 | N06022 | 2.4602 | NW 6022 | NiCr21Mo14W |

| Hastelloy C276 | N10276 | 2.4819 | NW 0276 | NiMo16Cr15W |