Specialized Products

ARK Stainless Inc. is a leading Manufacturer and Exporter of high-quality Specialized Products, headquartered in Mumbai, India.

Our specialized components are meticulously engineered to meet the highest industry standards, ensuring precision, durability, and superior performance.

We offer a diverse range of specialized fittings and components, including Mono Flanges, Bull Plugs, Adaptors, Refractory Anchors, Thermowells, and Couplings.

These products are designed for critical applications across industries such as Oil & Gas, Petrochemicals, Power Plants, Marine, and Heavy Engineering.

Manufactured with strict adherence to international quality standards, our specialized products enhance system efficiency, safety, and longevity in challenging industrial environments.

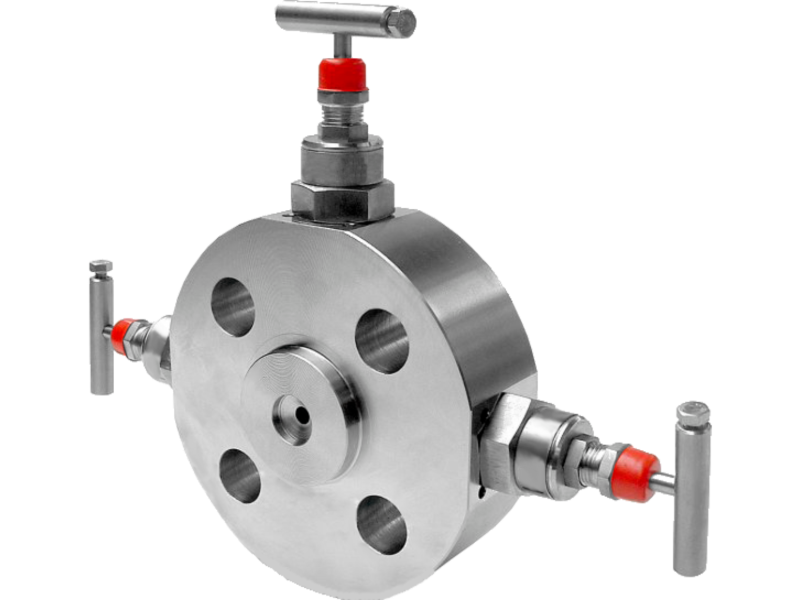

Mono Flange

A Mono Flange is a compact, lightweight, and high-performance piping component used to replace multiple connections with a single unit, minimizing leak paths.

It integrates valves and fittings into one compact design, reducing installation time and maintenance costs while improving system integrity.

Mono Flanges are widely used in applications requiring high-pressure, high-temperature, and corrosive resistance, particularly in Oil & Gas, Petrochemical, and Power Generation industries.

These flanges are designed with various configurations, including single block, double block & bleed (DBB), and vent options.

They are available in stainless steel, duplex steel, carbon steel, and high-alloy materials, ensuring excellent corrosion resistance and mechanical strength for critical operations.

Key Features:

-

1. Compact and lightweight design reduces installation space and weight.

-

2. Single, Double Block & Bleed (DBB), and Vent configurations available.

-

3. Eliminates multiple connections, reducing the risk of leaks.

-

4. Suitable for high-pressure and high-temperature applications.

-

5. Available in Stainless Steel, Duplex Steel, Carbon Steel, and High-Alloy materials.

Standard Dimensions & Specifications (ASME B16.5)

| Nominal Pipe Size (NPS) |

Pressure Rating |

Flange OD |

Bolt Circle Diameter |

Number of Bolt Holes |

Type |

| 1/2" |

150# |

90 mm |

60.3 mm |

4 |

Single Block |

| 1" |

300# |

125 mm |

82.5 mm |

4 |

Double Block & Bleed |

| 2" |

600# |

165 mm |

127 mm |

8 |

Single Block |

| 3" |

900# |

210 mm |

168.3 mm |

8 |

Double Block & Bleed |

Material Grades & Applications

| Material Type |

Grade |

Common Applications |

| Stainless Steel |

ASTM A182 F304, F316 |

Oil & gas, chemical processing, offshore platforms |

| Carbon Steel |

ASTM A105 |

High-pressure piping, petrochemical plants |

| Duplex Steel |

ASTM A182 F51, F53 |

Marine, desalination, aggressive environments |

| High-Alloy Steel |

ASTM A182 F44, F55 |

Extreme temperature and pressure applications |

Bull Plug

A Bull Plug is a tubular pipe fitting used to close the end of a pipeline or casing. It is commonly used in the oil and gas industry for pressure testing, isolation, or as a temporary or permanent pipeline closure.

Bull Plugs are manufactured in various materials, including stainless steel, carbon steel, and alloy steel, to suit different operational conditions. They come in different end connections such as threaded, beveled, or grooved, ensuring compatibility with diverse piping systems.

Key Features:

1. Used to seal or terminate pipe ends in oil and gas applications.

2. Available in threaded, beveled, and grooved end configurations.

3. Manufactured from stainless steel, carbon steel, and alloy steel.

4. Designed to withstand high pressure and harsh environments.

5. Commonly used in oilfields, pipelines, and high-pressure systems.

Dimensions & Specifications Table:

| Nominal Pipe Size (NPS) |

Outside Diameter (OD) |

End Connection |

Overall Length (L) |

| 1/2" | 21.3 mm | Threaded | 50 mm |

| 3/4" | 26.7 mm | Beveled | 60 mm |

| 1" | 33.4 mm | Grooved | 75 mm |

| 2" | 60.3 mm | Threaded | 100 mm |

| 4" | 114.3 mm | Beveled | 150 mm |

Pressure Ratings & Material Standards:

| Material |

Pressure Class (PSI) |

Temperature Rating (°C) |

ASTM Standard |

| Stainless Steel (SS 304/316) | 2000 PSI | -20°C to 650°C | ASTM A182 |

| Carbon Steel (A105) | 3000 PSI | -29°C to 427°C | ASTM A105 |

| Alloy Steel (A182 F22) | 5000 PSI | -46°C to 593°C | ASTM A182 |

| Duplex Steel (2205/2507) | 6000 PSI | -50°C to 315°C | ASTM A815 |

Adaptors

Adaptors are essential pipe fittings used to connect different types of piping components, ensuring seamless flow across varying diameters, materials, or connection types. These fittings help in smooth transitions in piping systems used in industries like oil & gas, chemical processing, water treatment, and power plants.

Adaptors are available in threaded, welded, and flanged configurations, made from high-quality materials such as carbon steel, stainless steel, alloy steel, and copper-nickel. They comply with ASME, ANSI, and ASTM standards for durability and efficiency.

Key Features:

1. Provides a seamless transition between different pipe sizes or materials.

2. Available in threaded, welded, and flanged types.

3. Manufactured following ASME, ANSI, and ASTM standards.

4. Commonly used in oil & gas, chemical, and water treatment industries.

5. Available in carbon steel, stainless steel, alloy steel, and copper-nickel.

Dimensions & Specifications Table (ASME Standard):

| Nominal Pipe Size (NPS) |

Connection Type |

Outer Diameter (OD) |

Wall Thickness |

Length |

| 1" | Threaded | 33.4 mm | 3.38 mm | 50 mm |

| 2" | Welded | 60.3 mm | 3.91 mm | 75 mm |

| 3" | Flanged | 88.9 mm | 5.49 mm | 100 mm |

| 4" | Threaded | 114.3 mm | 6.02 mm | 125 mm |

| 6" | Welded | 168.3 mm | 7.11 mm | 150 mm |

Pressure Ratings & Material Standards:

| Material |

Pressure Class (PSI) |

Temperature Rating (°C) |

ASTM Standard |

| Carbon Steel (A105) | 2000 PSI | -29°C to 425°C | ASTM A105 |

| Stainless Steel (SS 304/316) | 1500 PSI | -20°C to 650°C | ASTM A182 |

| Alloy Steel (A182 F11/F22) | 2500 PSI | -46°C to 593°C | ASTM A182 |

| Copper-Nickel (Cu-Ni 90/10) | 1000 PSI | -50°C to 300°C | ASTM B466 |

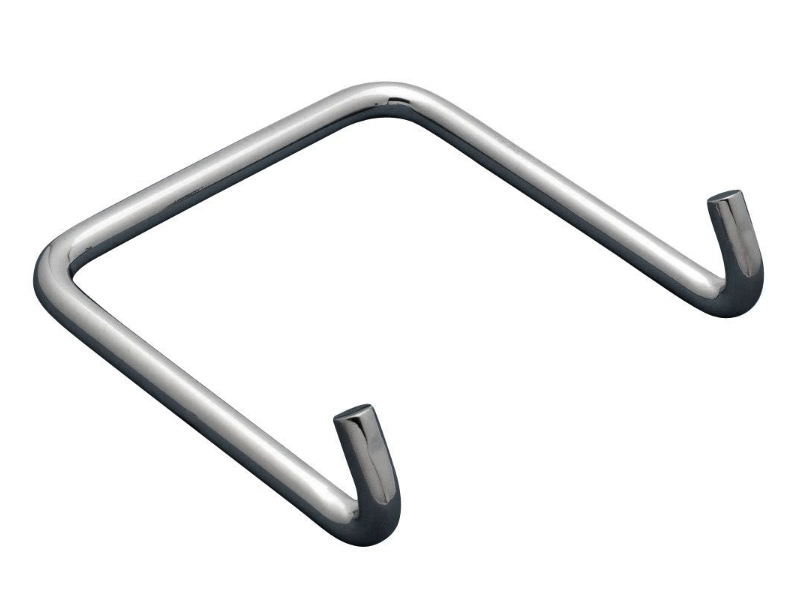

Refractory Anchors

Refractory Anchors are crucial components used to secure refractory linings in industrial furnaces, kilns, reactors, and other high-temperature processing units. These anchors ensure the stability and durability of refractory linings by holding them in place and preventing structural deformation due to thermal expansion and mechanical stress.

They are available in various shapes such as V-shaped, Y-shaped, U-shaped, and Corrugated Anchors. Common materials used include Stainless Steel (SS 304, SS 310, SS 316), Carbon Steel, Inconel, and other heat-resistant alloys, designed to withstand extreme temperatures and corrosive environments.

Key Features:

-

1. Provides structural stability to refractory linings.

-

2. Available in various shapes: V, Y, U, and Corrugated Anchors.

-

3. Manufactured using heat-resistant alloys for high-temperature applications.

-

4. Used in furnaces, kilns, reactors, and incinerators.

-

5. Resistant to thermal expansion, corrosion, and mechanical stress.

Dimensions & Specifications:

| Anchor Type |

Material |

Wire Diameter (mm) |

Length (mm) |

Max Operating Temperature (°C) |

| V-Anchor |

SS 310 |

5 mm |

50 - 300 |

1100°C |

| Y-Anchor |

Inconel 601 |

6 mm |

75 - 350 |

1250°C |

| U-Anchor |

SS 304 |

4 mm |

50 - 250 |

900°C |

| Corrugated Anchor |

Carbon Steel |

5.5 mm |

80 - 400 |

850°C |

Applications & Industry Usage:

| Industry |

Application |

Operating Conditions |

| Steel Industry |

Blast Furnaces & Ladle Furnaces |

High temperature & mechanical stress |

| Cement Plants |

Rotary Kilns & Clinker Coolers |

Thermal cycling & abrasion |

| Petrochemical Industry |

Reformers & Crackers |

Corrosive gases & extreme heat |

| Power Plants |

Boilers & Incinerators |

Flue gas corrosion & high-pressure conditions |

Thermowell

A Thermowell is a protective barrier used to safeguard temperature sensors such as thermocouples and RTDs from high pressure, corrosive fluids, and mechanical damage in industrial applications. It extends the lifespan of sensors by providing an isolation barrier between the measuring instrument and the process fluid.

Thermowells are widely used in industries like oil & gas, chemical processing, power plants, and food & beverage. They are available in materials such as stainless steel, carbon steel, Hastelloy, and Inconel, adhering to standards like ASME PTC 19.3, ASTM A182, and DIN 43772.

Key Features:

-

1. Provides protection to temperature sensors in high-pressure and corrosive environments.

-

2. Available in threaded, flanged, and welded configurations.

-

3. Compatible with various temperature measuring instruments.

-

4. Designed as per ASME PTC 19.3 standards for accuracy and reliability.

-

5. Used in industries requiring precise temperature monitoring and control.

Dimensions & Specifications Table (ASME PTC 19.3 Standard):

| Nominal Bore (NB) |

Insertion Length (U) |

Shank Diameter |

Process Connection |

Material |

| 1/2" |

100 mm |

12 mm |

Threaded |

SS 304 |

| 3/4" |

150 mm |

16 mm |

Flanged |

SS 316 |

| 1" |

200 mm |

22 mm |

Welded |

Hastelloy |

| 1 1/2" |

250 mm |

27 mm |

Threaded |

Inconel 600 |

Pressure Ratings & Material Standards:

| Material |

Pressure Class (PSI) |

Temperature Rating (°C) |

ASTM Standard |

| Stainless Steel 304 |

3000 PSI |

-50°C to 650°C |

ASTM A182 |

| Stainless Steel 316 |

4000 PSI |

-50°C to 870°C |

ASTM A479 |

| Hastelloy C276 |

5000 PSI |

-100°C to 1100°C |

ASTM B574 |

| Inconel 600 |

6000 PSI |

-200°C to 1250°C |

ASTM B166 |

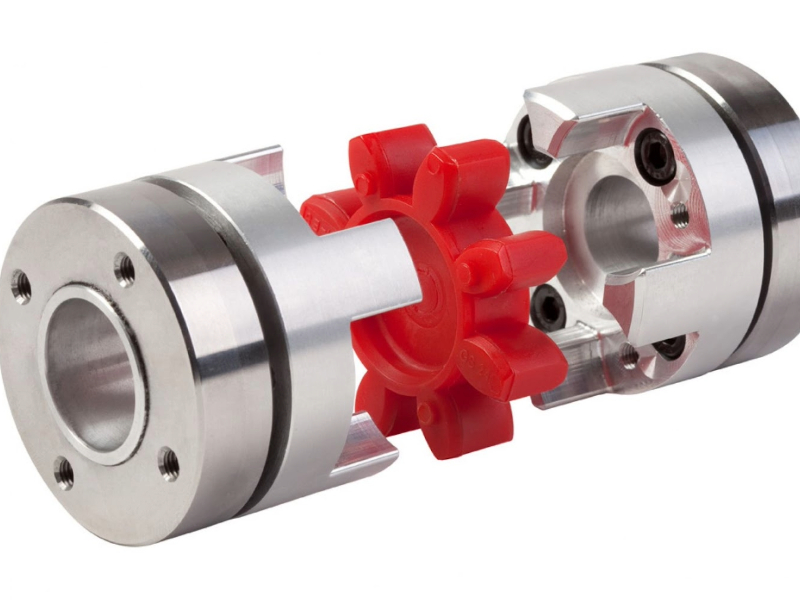

Couplings

A Pipe Coupling is a short length of pipe used to connect two pipes together, ensuring a secure and leak-proof joint. Couplings are essential for pipeline repair, extension, and redirection in various industries, including oil & gas, water supply, chemical processing, and power plants.

These fittings come in various types such as full coupling, half coupling, and reducing coupling. They are available in multiple materials like stainless steel, carbon steel, alloy steel, and PVC, complying with ASME, ASTM, and API standards.

Key Features:

1. Provides a secure and leak-proof connection.

2. Available in full, half, and reducing variations.

3. Resistant to corrosion and high pressure.

4. Used in plumbing, pipelines, and industrial applications.

5. Manufactured as per ASME, ASTM, and API standards.

Dimensions & Specifications:

| Type |

Size (NPS) |

Length (mm) |

Wall Thickness |

Material |

| Full Coupling | 1" | 50 mm | Sch 40 | SS 304 |

| Half Coupling | 2" | 40 mm | Sch 80 | CS A105 |

| Reducing Coupling | 3" x 2" | 60 mm | Sch 160 | Duplex 2205 |

| Full Coupling | 4" | 80 mm | XXS | Alloy Steel A182 F11 |