ARK Stainless Inc. is a leading Manufacturer and Exporter of high-quality Piping Spools located in Mumbai, India. We specialize in fabricating precision-engineered Piping Spools using the finest raw materials, rigorously tested and controlled by our skilled professionals to ensure exceptional durability and accuracy.

Each of our Piping Spools is manufactured in strict accordance with both National and International Industrial Standards, ensuring seamless integration into complex piping systems. Our commitment to quality and innovation has made us a trusted supplier across industries, including Oil & Gas, Power Plants, Chemical Processing, and Water Treatment, delivering superior reliability and efficiency in every project.

| Material | Standard | Available Grades | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| Stainless Steel | ASTM A312 / A358 / A778 | 304 | 304L | 316 | 316L | 317L | 321 | 347 | 904L | ||

| ASTM A790 / A928 | Duplex 2205 | Super Duplex 2507 | |||||||||

| Alloy Steel | ASTM A335 | P1 | P5 | P9 | P11 | P22 | P91 | ||||

| ASTM A106 / A53 | Grade A | Grade B | Grade C | WPHY 42 | WPHY 46 | WPHY 52 | WPHY 60 | WPHY 65 | WPHY 70 | ||

| Nickel Alloy | ASTM B161 / B163 | Nickel 200 | Nickel 201 | Inconel 600 | Inconel 625 | Inconel 800 | Inconel 825 | Hastelloy C22 | Hastelloy C276 | Monel 400 | |

| ASTM B338 / B466 | Titanium Gr.2 | Titanium Gr.5 | Cu-Ni 70/30 | Cu-Ni 90/10 | |||||||

| High Nickel Alloys | ASTM B163 / B333 / B622 / B564 | Nickel 200 | Nickel 201 | Alloy 20 | Incoloy 800 | Incoloy 825 | Monel 400 | Monel K500 | Hastelloy C22 | Hastelloy C276 | |

| Inconel | ASTM B163 / B167 / B564 | Inconel 600 | Inconel 601 | Inconel 625 | Inconel 718 | Inconel 800 | Inconel 825 | ||||

| Titanium | ASTM B348 / B381 / B861 | Grade 1 | Grade 2 | Grade 5 | Grade 7 | Grade 9 | Grade 12 | ||||

| Monel | ASTM B564 / B865 | Monel 400 | Monel K500 | ||||||||

| Hastelloy | ASTM B622 / B619 / B564 | Hastelloy C22 | Hastelloy C276 | Hastelloy B2 | Hastelloy X | ||||||

| Duplex & Super Duplex SS | ASTM A790 / A815 / A182 | Duplex 2205 | Duplex 2304 | Super Duplex 2507 | Super Duplex Zeron 100 | UNS S32750 | UNS S32760 | UNS S31803 | |||

| Spool No. | Material | Pipe Size (NPS) | Wall Thickness (mm) | Length (mm) | Weight (kg) | Joint Type | Weld Type | Chemical Composition (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Cr | Ni | Other | ||||||||

| SP001 | Stainless Steel (304L) | 6” | 4.78 | 1500 | 45.6 | Butt Weld | GTAW | ≤0.03 | 2.00 | 18-20 | 8-10 | Si: 1.00 |

| SP002 | Carbon Steel (ASTM A106 Gr. B) | 8” | 6.35 | 2000 | 78.2 | Flanged | SMAW | ≤0.30 | 1.20 | - | - | Fe: Balance |

| SP003 | Duplex Steel (UNS S32205) | 10” | 9.27 | 2500 | 120.5 | Socket Weld | GTAW | ≤0.03 | 2.00 | 21-23 | 4.5-6.5 | Mo: 2.5-3.5 |

| SP004 | Super Duplex Steel (UNS S32750) | 12” | 10.31 | 3000 | 180.8 | Butt Weld | SMAW | ≤0.03 | 1.20 | 24-26 | 6-8 | Mo: 3-4.5 |

| SP005 | Nickel Alloy (Monel 400) | 6” | 7.11 | 1800 | 85.3 | Flanged | GTAW | ≤0.30 | 2.00 | - | Balance | Cu: 28-34 |

| Spool Number | Pipe Size (Inch) | Pipe Length (mm) | End Connection | Fitting Details | Weld Type | Material Specification | Weight (kg) | ||

|---|---|---|---|---|---|---|---|---|---|

| Elbow | Tee | Reducer | |||||||

| SP-001 | 6" | 1500 | Flanged | 2 x 90° (SCH 40) | - | - | Butt Weld | ASTM A106 Gr. B | 35 |

| SP-002 | 8" | 1800 | Butt Weld | 1 x 45° (SCH 80) | 1 x Tee | - | Butt Weld | ASTM A53 Gr. B | 48 |

| SP-003 | 10" | 2000 | Flanged | - | 1 x Tee | 1 x 10" x 6" | Butt Weld | ASTM A106 Gr. B | 62 |

| SP-004 | 12" | 2200 | Socket Weld | 2 x 90° (SCH 40) | - | 1 x 12" x 8" | Butt Weld | ASTM A333 Gr. 6 | 80 |

| Material | Grade | Pressure-Temperature Ratings (PSI) | Standard | ||||

|---|---|---|---|---|---|---|---|

| -20°F to 100°F | 200°F | 400°F | 600°F | 800°F | |||

| Carbon Steel | ASTM A106 Gr. B | 300 | 275 | 250 | 225 | 200 | ASME B31.3 |

| ASTM A53 Gr. B | 290 | 265 | 240 | 215 | 190 | ||

| ASTM A333 Gr. 6 | 280 | 260 | 230 | 210 | 185 | ||

| Stainless Steel | ASTM A312 TP304 | 400 | 375 | 350 | 320 | 290 | ASME B31.3 |

| ASTM A312 TP316 | 410 | 385 | 360 | 330 | 300 | ||

| ASTM A312 TP321 | 390 | 365 | 340 | 310 | 280 | ||

| Alloy Steel | ASTM A335 P11 | 500 | 470 | 440 | 400 | 360 | ASME B31.1 |

| ASTM A335 P22 | 520 | 490 | 460 | 420 | 380 | ||

| Duplex Steel | ASTM A790 UNS S31803 | 600 | 580 | 550 | 520 | 490 | ASME B31.3 |

| ASTM A790 UNS S32205 | 620 | 600 | 570 | 540 | 510 | ||

| Nickel Alloy | ASTM B366 UNS N06600 | 700 | 680 | 650 | 620 | 590 | ASME B31.3 |

| ASTM B366 UNS N08825 | 720 | 700 | 670 | 640 | 610 | ||

| Material | Pipe Standard | Dimensional Tolerances (mm) | Wall Thickness Tolerances (%) | Standard | ||||

|---|---|---|---|---|---|---|---|---|

| OD (Outer Diameter) | Length (Pipe Cut Tolerance) | End Preparation | Min | Max | Average | |||

| Carbon Steel | ASTM A106 Gr. B | ±0.5 | ±2.0 | ±1.0 | -12.5% | +12.5% | ±10% | ASME B31.3 / B31.1 |

| ASTM A53 Gr. B | ±0.6 | ±2.0 | ±1.2 | -12.5% | +12.5% | ±10% | ||

| ASTM A333 Gr. 6 | ±0.7 | ±2.5 | ±1.5 | -10% | +10% | ±8% | ||

| Stainless Steel | ASTM A312 TP304 | ±0.5 | ±2.0 | ±1.0 | -10% | +10% | ±8% | ASME B31.3 / B31.1 |

| ASTM A312 TP316 | ±0.6 | ±2.0 | ±1.2 | -10% | +10% | ±8% | ||

| ASTM A358 TP321 | ±0.7 | ±2.5 | ±1.5 | -8% | +8% | ±7% | ||

| Duplex Stainless Steel | ASTM A790 UNS S31803 | ±0.6 | ±2.0 | ±1.2 | -10% | +10% | ±8% | ASME B31.3 |

| ASTM A790 UNS S32205 | ±0.7 | ±2.5 | ±1.5 | -8% | +8% | ±7% | ||

| ASTM A790 UNS S32750 | ±0.8 | ±3.0 | ±1.8 | -8% | +8% | ±7% | ||

| Nickel Alloy | ASTM B366 UNS N06600 | ±0.5 | ±2.0 | ±1.0 | -10% | +10% | ±8% | ASME B31.3 |

| ASTM B366 UNS N08825 | ±0.6 | ±2.5 | ±1.2 | -8% | +8% | ±7% | ||

| ASTM B366 UNS N10276 | ±0.7 | ±3.0 | ±1.5 | -8% | +8% | ±7% | ||

Piping spools are pre-fabricated pipe sections that are widely used in industries to enhance efficiency, reduce site work, and ensure precise alignment. Their applications span across various sectors, including:

Used in offshore and onshore installations for fast and reliable pipeline assembly.

Ensures accurate and leak-proof connections in high-pressure chemical processing plants.

Used in steam, cooling, and fuel transport systems within thermal and nuclear power stations.

Pre-fabricated spools ensure quick installation in desalination and wastewater treatment facilities.

Maintains hygienic and sterile conditions in fluid transport for pharmaceutical manufacturing.

Stainless steel spools provide corrosion resistance and compliance with sanitary regulations.

Used in ship engine rooms, ballast water systems, and offshore platform piping networks.

Prefabricated spools simplify complex pipeline installations in high-rise buildings and industrial projects.

Piping spools are prefabricated sections of piping systems that include pipes, flanges, elbows, tees, and other fittings. The manufacturing process ensures high precision, efficiency, and compliance with project requirements.

Pipes, fittings, flanges, and valves are selected based on project specifications and material standards such as carbon steel, stainless steel, or alloy steel.

Pipes are cut to required lengths using CNC cutting, plasma cutting, or saw cutting, followed by beveling to prepare the ends for welding.

Components like pipes, elbows, tees, and flanges are aligned and tacked together based on isometric drawings and spool fabrication specifications.

Welding is carried out using processes such as GTAW (TIG), SMAW (Stick), or GMAW (MIG) while following qualified welding procedures (WPS & PQR).

PWHT is performed for specific materials to reduce residual stresses and enhance metallurgical properties.

Non-destructive testing (NDT), hydrostatic testing, and dimensional checks ensure compliance with ASME and API standards.

Piping spools are sandblasted, pickled, and coated with epoxy, galvanization, or painting for corrosion resistance.

Each spool is tagged with unique identifiers and documented with material test reports (MTR), welding logs, and inspection records.

Spools are packed with wooden supports, plastic wrapping, or crates for safe transportation to the installation site.

A Straight Spool is a pre-fabricated pipe section with flanges or beveled ends, designed for easy connection in a pipeline. These spools serve as essential components in piping systems, ensuring precise alignment and efficient fluid flow. Straight spools are commonly used in industries such as oil & gas, power plants, chemical processing, and water treatment facilities.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Length (L) | End Type |

|---|---|---|---|

| 1/2" | 21.3 mm | 1000 mm | Beveled |

| 3/4" | 26.7 mm | 1200 mm | Flanged |

| 1" | 33.4 mm | 1500 mm | Plain |

| 1 1/2" | 48.3 mm | 2000 mm | Beveled |

| 2" | 60.3 mm | 2500 mm | Flanged |

| 3" | 88.9 mm | 3000 mm | Beveled |

| 4" | 114.3 mm | 3500 mm | Flanged |

| 6" | 168.3 mm | 4000 mm | Beveled |

| 8" | 219.1 mm | 4500 mm | Flanged |

An Elbow Spool is a prefabricated piping section that consists of a pipe segment and an elbow welded together. It is used to change the direction of fluid flow in piping systems while reducing field welding and installation time. These spools are commonly used in industries such as oil & gas, chemical processing, and water treatment. Available in different angles like 45° and 90°, elbow spools ensure efficient fluid movement with minimal pressure drop.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Center-to-Face (A) 90° Elbow | Center-to-Face (B) 45° Elbow | Wall Thickness (SCH 40) |

|---|---|---|---|---|

| 1/2" | 21.3 mm | 38 mm | 16 mm | 2.77 mm |

| 3/4" | 26.7 mm | 38 mm | 19 mm | 2.87 mm |

| 1" | 33.4 mm | 51 mm | 22 mm | 3.38 mm |

| 1 1/4" | 42.2 mm | 64 mm | 25 mm | 3.56 mm |

| 1 1/2" | 48.3 mm | 76 mm | 29 mm | 3.68 mm |

| 2" | 60.3 mm | 102 mm | 35 mm | 3.91 mm |

| 3" | 88.9 mm | 152 mm | 57 mm | 5.49 mm |

| 4" | 114.3 mm | 203 mm | 76 mm | 6.02 mm |

| 6" | 168.3 mm | 305 mm | 114 mm | 7.11 mm |

| 8" | 219.1 mm | 406 mm | 152 mm | 8.18 mm |

A Tee Spool is a buttweld pipe fitting used to split or combine the flow of fluids in piping systems. It features one inlet and two outlets (or vice versa) arranged at a 90° angle to the main pipeline. The two primary types include Equal Tee, where all three branches have the same diameter, and Reducing Tee, where one or more outlets have a smaller diameter than the main run. Tee Spools are extensively used in oil & gas, chemical processing, and water distribution pipelines.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Run Center-to-End (A) | Branch Center-to-End (B) | Wall Thickness (SCH 40) |

|---|---|---|---|---|

| 1/2" | 21.3 mm | 25 mm | 25 mm | 2.77 mm |

| 3/4" | 26.7 mm | 29 mm | 29 mm | 2.87 mm |

| 1" | 33.4 mm | 38 mm | 38 mm | 3.38 mm |

| 1 1/4" | 42.2 mm | 48 mm | 48 mm | 3.56 mm |

| 1 1/2" | 48.3 mm | 57 mm | 57 mm | 3.68 mm |

| 2" | 60.3 mm | 64 mm | 64 mm | 3.91 mm |

| 3" | 88.9 mm | 76 mm | 76 mm | 5.49 mm |

| 4" | 114.3 mm | 95 mm | 95 mm | 6.02 mm |

| 6" | 168.3 mm | 143 mm | 143 mm | 7.11 mm |

| 8" | 219.1 mm | 191 mm | 191 mm | 8.18 mm |

A Reducer Spool is a prefabricated pipe section that transitions between different pipe diameters to ensure smooth fluid flow. It is used in piping systems to connect pipes of varying sizes while maintaining pressure integrity and minimizing turbulence.

| Nominal Pipe Size (NPS) | Large End Diameter (D1) | Small End Diameter (D2) | Reducer Length (H) | Wall Thickness (SCH 40) |

|---|---|---|---|---|

| 2" x 1" | 60.3 mm | 33.4 mm | 76 mm | 3.91 mm |

| 3" x 2" | 88.9 mm | 60.3 mm | 89 mm | 5.49 mm |

| 4" x 2" | 114.3 mm | 60.3 mm | 102 mm | 6.02 mm |

| 6" x 4" | 168.3 mm | 114.3 mm | 127 mm | 7.11 mm |

| 8" x 6" | 219.1 mm | 168.3 mm | 152 mm | 8.18 mm |

| 10" x 8" | 273.0 mm | 219.1 mm | 178 mm | 9.27 mm |

| 12" x 10" | 323.9 mm | 273.0 mm | 203 mm | 9.52 mm |

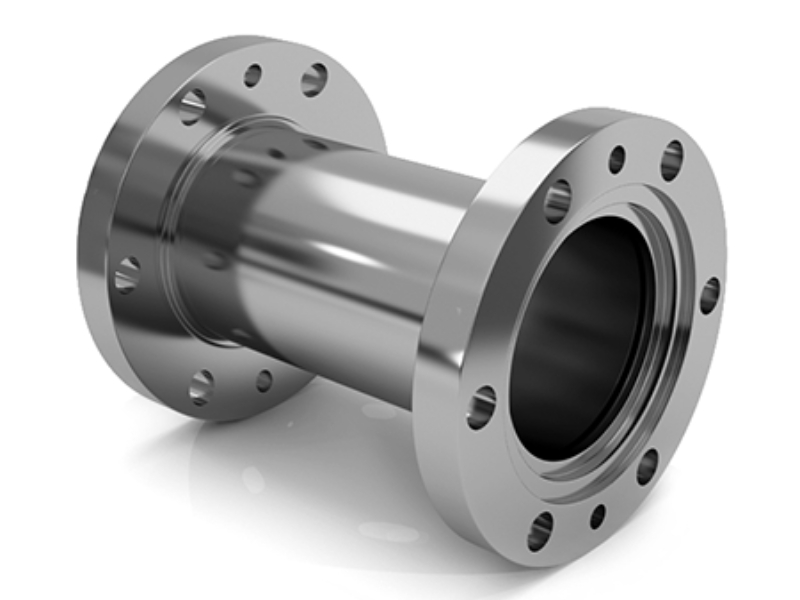

A Flange Spool is a pre-fabricated piping assembly consisting of flanges and pipe sections, designed for easy installation and connection in pipeline systems. These spools reduce on-site welding, improve installation efficiency, and enhance structural integrity. They are widely used in oil & gas, petrochemical, water treatment, and power plants.

| Nominal Pipe Size (NPS) | Flange Outer Diameter (OD) | Bolt Circle Diameter (BCD) | Number of Bolts | Bolt Hole Diameter | Spool Length (Customizable) |

|---|---|---|---|---|---|

| 1/2" | 89 mm | 60.3 mm | 4 | 15.7 mm | Custom |

| 1" | 114 mm | 79.4 mm | 4 | 15.7 mm | Custom |

| 2" | 165 mm | 127.0 mm | 4 | 19.0 mm | Custom |

| 4" | 279 mm | 215.9 mm | 8 | 22.4 mm | Custom |

| 6" | 356 mm | 269.9 mm | 8 | 25.4 mm | Custom |

| 8" | 419 mm | 330.2 mm | 8 | 28.4 mm | Custom |

| 10" | 508 mm | 387.4 mm | 12 | 31.8 mm | Custom |

| 12" | 610 mm | 450.8 mm | 12 | 34.9 mm | Custom |