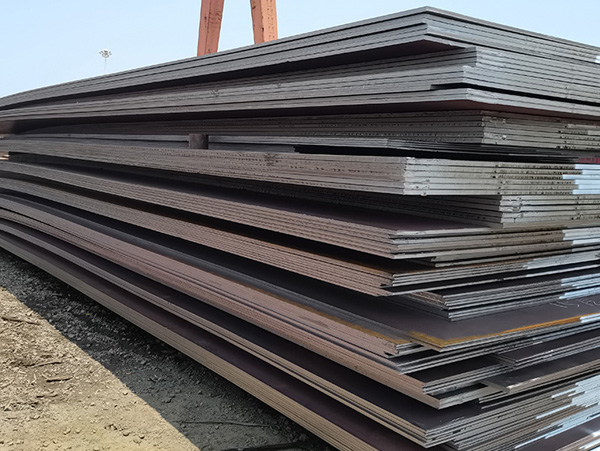

Suppliers, Traders, Exporters and Stockists of Xar 400 Abrasion Resistant Steel Plates

ARK Stainless is a leading supplier, trader, stockist, and exporter of Xar 400 Wear Abrasion Resistant Plates. As one of the top importers and stockists of Xar 400 Plates, we proudly offer this exceptional wear plate series from Nippon Sumitomo Steel Metal Corporation, Japan.

The use of Xar 400 Abrasion Resistant Plates significantly reduces the weight of structural members exposed to severe abrasive conditions. Compared to regular steel, Xar 400 Wear Resistant Plates minimize structural weight while providing substantial economic benefits. The adoption of high-performance abrasion-resistant Xar 400 will extend the service life of machinery and components, making it an ideal choice for demanding environments.

Our Xar 400 Wear Abrasion Resistant Sheet Plates are available in various sizes and thicknesses ranging from 3mm to 60mm. This versatility ensures that you can find the perfect fit for your specific application needs. Wear-resistant steel is particularly effective in areas subjected to high abrasion or wear, such as truck beds, attachments for diggers and earth movers, and processing applications in the mining industry.

The key quality of wear-resistant steels, including Xar 400 Plates, is their impressive hardness. We provide wear plates according to their hardness measured on the Brinell Hardness Test, typically in 400HB and 500HB grades. Steels with a high HB rating are designed for applications where wear or abrasion resistance is crucial. Using Xar 400 not only prolongs the lifespan of machinery but also enhances the reliability, durability, and safety of structures and equipment while reducing maintenance costs associated with wear and breakdown.

With a hardness over three times that of mild steel (120HB), Xar 400 offers optimal performance for construction machinery, skips, bulldozers, excavators, buckets, and conveyors. The steel undergoes quenching to provide superior wear resistance and may also be tempered to enhance hardness. Importantly, lower HB ratings offer good cold bending properties and excellent weldability, ensuring that performance is not compromised as hardness increases.

We proudly export Xar 400 Abrasion Resistant Steel Plates to a global clientele, including countries like the United Arab Emirates, Brazil, Russia, Bangladesh, Indonesia, Egypt, Qatar, Iran, Kuwait, Taiwan, Oman, South Africa, Saudi Arabia, Australia, Pakistan, and Malaysia. Choose ARK Stainless for your Xar 400 Plates needs and experience unmatched quality and performance in every application.

Applications of XAR 400

The steel may be used at the discretion of the purchaser for wear exposed structures.

- Excavating

- Mining

- Earth Moving Machinery

- Truck Dump Bodies

- Conveying

- Crushing

- Pulverizing Equipment

- Scrap Presses

- Paving moulds

- Switch Manufacturing

- Cement Plant Equipment

- Agricultural Machinery

The Processing and application techniques as a whole are of fundamental importance for the successful use of the products fabricated of this steel. The Processor / Fabricator must assure himself that his design and work methods are appropriate for the material are state of the art and are suitable for the envisaged purpose.

Cold forming

The products made of this steel are suitable for cold bending provided, that consideration is given to the high hardness. The formability of steel decreases with increasing hardness. This has to be kept in mind when forming.

The forming must take place at a slow and steady rate, the cut edges must be deburred and the plates heated, if necessary, prior to the forming. A final stress-relieving is not necessary for this steel.

Machinability

In spite of its high wear resistance, the steel exhibits good machinability if sufficiently heavy machine-tools and sharp carbide-tipped tools are used. The feed rate and cutting speed have to be adjusted to the high hardness of the material.

Heat treatment

Plates of the XAR 400 grade receive the required properties as a result of austenitizing and follow-on quenching in special facilities and, where applicable, tempering below Ac1. Direct quenching after hot-rolling is considered equivalent to conventional quenching. The heat treatment depends on the chemical composition and the product thickness. To avoid hardness losses, the steel must not be heated above 250 °C.

Thermal cutting

Preferably the flame-cutting process is used. For small product thicknesses, however, the plasma cutting process is used in the interest of minimum distortion.

Preheating is not normally necessary when flame-cutting thicknesses up to around 30 mm. However, if the workpiece temperature is below + 5 °C, or the cut edges are to be cold-formed in the course of further processing, preheating to about 150 °C should be considered in the interest of cold cracking resistance.

Welding

If due consideration is given to the general rules for welding, this steel is weldable both manually and automatically. To prevent cold cracking in the welded joints only welding consumables giving welds of very low hydrogen content should be used. Preheating is not generally necessary for welding with austenitic filler metals. Preheating may be necessary for welding with ferritic filler metals.