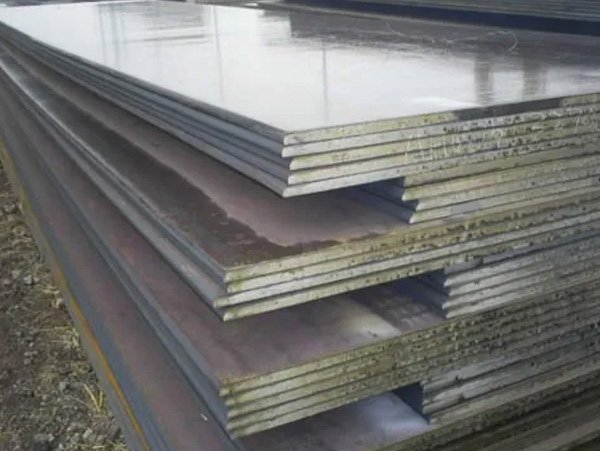

Suppliers, Traders, Exporters and Stockists of Dillidur 450 Abrasion Resistant Steel Plates

ARK Stainless is a leading supplier, trader, stockist, and exporter of Dillidur 450 Abrasion Resistant Plates. Known for its remarkable durability, Dillidur 450 Plates have an average hardness of 450 HBW in the delivery condition, achieved through a precise quenching process that enhances its mechanical properties. This makes Dillidur 450 Wear Resistant Plates an ideal choice for applications where elevated resistance to wear is essential, without compromising on workability and weldability.

Industries relying on heavy machinery, such as earth-moving and loading operations, benefit from the strength of Dillidur 450. These plates are commonly used in equipment like dredgers, skip cars, conveying plants, trucks, cutting edges, knives, breakers, and waste elimination and recycling plants. The Dillidur 450 wear-resistant steel plates offer outstanding machinability and superior welding performance, making them an optimal solution for high-wear environments.

As trusted suppliers, stockists, and exporters of Dillidur 450 Plates, ARK Stainless is dedicated to providing top-quality products that meet the rigorous demands of various industrial applications. Choose Dillidur 450 for unparalleled performance and reliability in your projects, and trust in our expertise to deliver excellence.

Cold forming

Dillidur 450 is an exceptional choice for applications requiring wear-resistant materials, known for its impressive hardness and strength. Remarkably, this steel can be cold-formed through bending, making it versatile for various engineering applications. However, it’s crucial to note that as the yield strength of Dillidur 450 increases, so does the force needed for forming operations, even if the thickness of the plate remains constant. This relationship can lead to increased spring-back, necessitating careful handling during the cold forming process.

To minimize the risk of cracking, it is essential to grind flame-cut or sheared edges in the areas designated for cold forming. Additionally, rounding the outside edges of the bend can help reduce tension stress and improve the integrity of the final product. Implementing these techniques not only enhances the performance of Dillidur 450 wear-resistant plates but also ensures safety during the bending operation.

Safety measures are paramount throughout the processing of Dillidur 450. Operators must be vigilant to avoid any hazards associated with potential fractures of the workpiece. Proper training and equipment should be employed to mitigate risks, ensuring a secure and efficient working environment.

Incorporating Dillidur 450 into your manufacturing processes provides not only superior wear resistance but also adaptability in forming applications. By following best practices in cold forming, you can maximize the benefits of this remarkable steel while prioritizing safety and quality in your operations.

Hot forming

Dillidur 450 is renowned for its exceptional hardness, achieved through accelerated cooling from the austenitizing temperature. This unique property makes it a preferred choice in demanding applications. However, when it comes to hot forming, there are important considerations to ensure minimal hardness loss. To maintain the desired hardness levels after hot forming, a renewed quenching treatment is essential.

It's crucial to recognize that the hardness resulting from this post-forming quenching may differ from the hardness measured in the delivery condition of the Dillidur 450 product brand by Dillinger 4/6. This variance stems from the differences in cooling conditions experienced at the fabricator's facility compared to those during the original plate production.

For effective hot forming, Dillidur 450 can be heated to approximately 200 °C (390 °F) without significant loss of hardness. In some cases, it can withstand temperatures up to 250 °C (482 °F) for short periods, making it versatile for various fabrication processes.

Understanding these nuances in the hot forming of Dillidur 450 is vital for manufacturers seeking to leverage its wear-resistant properties while ensuring the integrity of the material remains intact. By adhering to proper heating guidelines and post-forming treatments, you can optimize the performance of Dillidur 450 in your applications, making it a reliable choice for high-stress environments.

Flame cutting and welding

When it comes to working with Dillidur 450 Abrasion Resistant Steel Plates, precise flame cutting and welding techniques are essential to maintain the material's integrity and performance. For effective flame cutting, specific minimum temperatures must be adhered to, depending on the plate thickness. For plates up to 26 mm thick, a minimum temperature of 50 °C (122 °F) is recommended. For thicknesses between 26 mm and 52 mm, the temperature should rise to 100 °C (212 °F), and for thicker plates, it is crucial to achieve at least 125 °C (257 °F).

In addition to flame cutting, manual arc welding is another vital process for joining Dillidur 450 plates. When welding, it’s important to use basic coated rods with very low residual moisture to ensure a strong bond. If necessary, follow the manufacturer's instructions for drying the rods prior to use. This attention to detail in both flame cutting and welding techniques ensures optimal performance and durability in applications requiring high wear resistance.

At ARK Stainless, we pride ourselves on being trusted suppliers, stockists, and exporters of Dillidur 450 Abrasion Resistant Steel Plates. Our products are available for clients across the globe, including regions such as the United Arab Emirates, Brazil, Russia, Bangladesh, Indonesia, Egypt, Qatar, Iran, Kuwait, Taiwan, Oman, South Africa, Saudi Arabia, Australia, Pakistan, and Malaysia.

Whether you're involved in construction, mining, or heavy machinery, Dillidur 450 is engineered to meet your demands. Explore our extensive inventory and discover how our high-quality steel plates can enhance your projects.