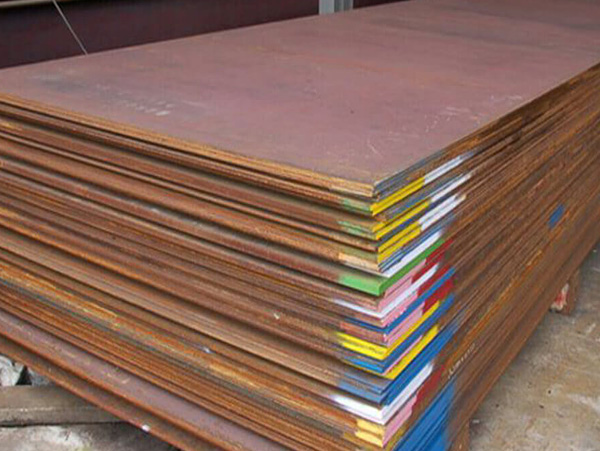

Suppliers, Traders, Exporters and Stockists of Rockstar 450 Abrasion Resistant Steel Plates

ARK Stainless is a premier supplier, stockist, and exporter of Rockstar 450 Abrasion Resistant Steel Plates, developed in our high-tech facility with advanced equipment to ensure top-notch performance in various applications. Our Rockstar 450 Plates are designed for demanding environments, combining superior wear resistance with hardness, toughness, and weldability. These attributes make Rockstar 450 Wear Resistant Plates ideal for use in mining and construction industries, especially in equipment like crushers, truck body liners, buckets, hoppers, beds, chutes, and conveyors.

Our Rockstar 450 Plates deliver outstanding durability and formability, maintaining hardness and strength even under extreme wear conditions. ARK Stainless offers custom sizing, thickness, and finishing options for Rockstar 450 Wear Resistant Plates, meeting the specific needs of our diverse clientele. Known for high impact resistance, these plates excel in heavy-duty applications, ensuring extended service life and reliable performance.

Available in hot and cold-rolled types with a variety of surface coatings, including EP, PE, HDP, SMP, and PVDF, the Rockstar 450 Plates are formulated with a carefully balanced composition of carbon, silicon, manganese, phosphorus, sulfur, chromium, nickel, molybdenum, and boron. This robust chemical makeup contributes to their excellent abrasion resistance and wear durability.

With options like Rockstar 400, 450, and 500 grades, each plate offers varying mechanical properties suited to specific application needs. The Rockstar 450 Abrasion Resistant Steel Plates provide exceptional tensile and yield strengths, ideal for high-impact, high-abrasion conditions. ARK Stainless is proud to supply these high-performance plates worldwide, exporting to markets in the UAE, Brazil, Russia, Bangladesh, Indonesia, Egypt, Qatar, Iran, and beyond.

For more details on Rockstar 450 Plates, including pricing, weight charts, and customization options, contact ARK Stainless, your trusted partner for premium wear-resistant steel solutions.

Rockstar 450 Plates: Unmatched Strength and Abrasion Resistance for Heavy-Duty Applications

Rockstar 450 Plates are top-tier abrasion-resistant steel plates crafted for industries demanding both strength and longevity under extreme conditions. Known for their remarkable hardness and wear resistance, Rockstar 450 Plates are particularly suited for applications involving high-impact and heavy wear, such as in mining, construction, and material handling. This durability is achieved through a specialized high-carbon alloy composition, ensuring the plates maintain their structural integrity while resisting deformation and abrasion even under intense usage.

The mechanical properties of Rockstar 450 Plates make them the preferred choice for equipment components like chutes, hoppers, liners, and buckets, where reliability is crucial. Their high tensile strength, coupled with excellent weldability and formability, allows these plates to withstand severe stresses without compromising on flexibility. Additionally, Rockstar 450 Plates exhibit impressive corrosion resistance, which makes them ideal for environments exposed to harsh elements or corrosive substances.

Available in various thicknesses and customizable to meet specific project requirements, Rockstar 450 Plates offer versatile solutions that excel in applications requiring prolonged service life and reduced maintenance. As a key player in abrasion-resistant steel, Rockstar 450 not only extends the lifespan of industrial equipment but also optimizes operational efficiency, making it a sound investment for companies looking to minimize downtime and maximize durability.

Dimensions

| USED FOR | DIMENSIONS | STANDARDS |

|---|---|---|

| Wear Resistant | T: 2.5 - 80 mm W: Up to 3200 mm L: Up to 12000 mm |

EN 10163-2 EN 10051 EN 10029 |

Mechanical Properties

| Product | Thickness (mm) | Width (mm) | Length (mm) | Hardness (HBW) | Typical yield strength Rp0.2 (MPa) | Typical tensile strength Rm (MPa) | Typical elongation A (%) |

|---|---|---|---|---|---|---|---|

| Sheet | 2.50 - 8.00 | 1000 - 1700 | 2000 - 12000 | 420 - 500 | 1250 | 1450 | 9 |

| Plate | 6.50 - 40.00 | 1800 - 3200 | 2000 - 12000 | 420 - 500 | 1200 | 1450 | 9 |

| Plate | 40.01 - 60.00 | 2000 - 2500 | 4000 - 9500 | 420 - 500 | 1250 | 1450 | 9 |

| Plate | 60.01 - 80.00 | 2000 - 2500 | 4000 - 6900 | 420 - 500 | 1250 | 1450 | 9 |

Chemical Composition

| Product | C (max %) | Si (max %) | Mn (max %) | P (max %) | S (max %) | Cr (max %) | Ni (max %) | Mo (max %) | B (max %) |

|---|---|---|---|---|---|---|---|---|---|

| Plate | 0.26 | 0.80 | 1.70 | 0.025 | 0.015 | 1.50 | 1.00 | 0.50 | 0.005 |

| Sheet | 0.23 | 0.50 | 1.60 | 0.025 | 0.010 | 1.20 | 1.00 | 0.25 | 0.005 |

Mechanical Properties for Rockstar 450 High Tensile Plate

| Hardness | Yield Strength (MPa) | Tensile Strength (MPa) | % Elongation (L0=50 mm) | Impact at -20°C (In Joules) |

|---|---|---|---|---|

| Typical values for 20 mm plate thickness | 1150 | 1350 | 12 | 30 |