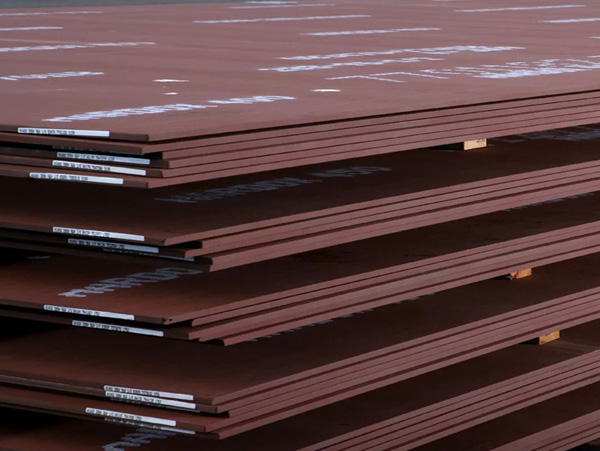

Suppliers, Traders, Exporters and Stockists of Rockhard 400 BHN Abrasion Resistant Steel Plates

ARK Stainless is a leading supplier, stockist, and exporter of Rockhard 400 BHN Abrasion Resistant Steel Plates, delivering durable, high-performance solutions worldwide. With a focus on quality and reliability, we offer Rockhard 400 BHN Plates that meet both national and international standards. Manufactured using top-grade raw materials from trusted sources, our Rockhard 400 BHN Wear Resistant Plates are crafted with precision through advanced technology and modern machinery, ensuring exceptional accuracy and finish.

Rockhard 400 BHN Plates are engineered with hardened steel, achieving a nominal Brinell hardness of 400 HBW, which provides outstanding wear and abrasion resistance. Known for their enhanced formability and welding capabilities, these plates exhibit excellent resistance in high-temperature environments, making them ideal for heavy-duty applications. With refined grain structure and impressive toughness, Rockhard 400 BHN Plates ensure high strength and durability, along with reliable sliding wear resistance.

These abrasion-resistant plates are produced through tempering and quenching, ensuring superior mechanical properties for demanding applications. Available with thermally cut and sheared edges or custom length, Rockhard 400 BHN Abrasion Resistant Steel Plates are known for their formability, durability, and adaptability in rugged environments. Common uses include quarries, construction machinery, concrete molds, mining machinery, cement plants, and more, where exceptional wear resistance is essential.

We export Rockhard 400 BHN Wear Resistant Plates to markets across the globe, including the United Arab Emirates, Brazil, Russia, and several other countries in the Middle East, Asia, and beyond. Contact ARK Stainless for a range of options to extend the life of equipment and reduce maintenance costs with our industry-leading Rockhard 400 BHN Plates.

Rockhard 400 BHN Plates are renowned for their high abrasion resistance, strength, and durability, making them an ideal choice for industries facing severe wear and tear conditions. Designed with a nominal hardness of 400 Brinell (HBW), these plates provide exceptional toughness without compromising on formability or weldability. Rockhard 400 BHN Plates are widely used across mining, construction, cement, and recycling sectors, where equipment is subjected to intense abrasion and impact.

Each Rockhard 400 BHN Plate is engineered through a process of quenching and tempering, which enhances its mechanical properties and provides a robust surface that withstands heavy loads, prolonged friction, and high-temperature applications. Their superior resistance to wear helps extend the operational life of machinery components like chutes, crushers, hoppers, conveyors, and liners, thereby minimizing downtime and maintenance costs.

ARK Stainless, a trusted supplier and exporter of Rockhard 400 BHN Plates, offers a range of thicknesses, sizes, and customizable finishes to meet the specific requirements of global clients. These plates are available in various surface finishes and thicknesses, ensuring they can be tailored for any high-impact industrial setting. Each plate undergoes rigorous testing for hardness, strength, and flatness to ensure top-notch quality and performance.

With their high durability and adaptability, Rockhard 400 BHN Plates are a preferred material for challenging applications, delivering reliability, longevity, and protection across some of the world’s toughest environments.

Specification

| Item | Abrasion Resistant Plate |

|---|---|

| Material | BHN 400, SUMIHARD, BRINAR, DUROSTAT, DILLIDUR, JFE EVERHARD. |

| Thickness | 3 - 200mm |

| Width | 500 - 3000mm |

| Length | 1000 - 12000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

Chemical Composition Of BHN 400 Plates

| Plate | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV | CET |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3- 6 | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.50 | 0.25 | 0.25 | 0.004 | 0.41 | 0.28 |

| 3-(8) | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.30 | 0.25 | 0.25 | 0.004 | 0.33 | 0.23 |

| 8 - 20 | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.50 | 0.25 | 0.25 | 0.004 | 0.37 | 0.27 |

| (20)-32 | 0.18 | 0.70 | 1.60 | 0.025 | 0.01 | 1.00 | 0.25 | 0.25 | 0.004 | 0.48 | 0.29 |

| (32)-45 | 0.22 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 0.50 | 0.60 | 0.004 | 0.57 | 0.31 |

| (45)-51 | 0.22 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 0.50 | 0.60 | 0.004 | 0.57 | 0.38 |

| (51)-80 | 0.27 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 1.00 | 0.60 | 0.004 | 0.65 | 0.41 |

| (80)-130 | 0.32 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 1.50 | 0.60 | 0.004 | 0.73 | 0.48 |

Mechanical Properties Of BHN 400 Plates

| Grade | Mechanical Property | Charpy V Impact Test | |||

|---|---|---|---|---|---|

| BHN 400 | Yield | Tensile | Elongation | Degree | longitudinal |

| Min Mpa | Mpa | Min % | -40 | J | |

| 1000 | 1250 | 10 | 45 | ||